Machining on Lathe

Lathe Booking Time: 3 Hrs

Max CMF Points Earned: 400 Pts.

Facility to Book : Centre Lathe - 3 Jaw

Lathe Machine

Learn a basic introduction to the Lathe Machine before performing any operation.

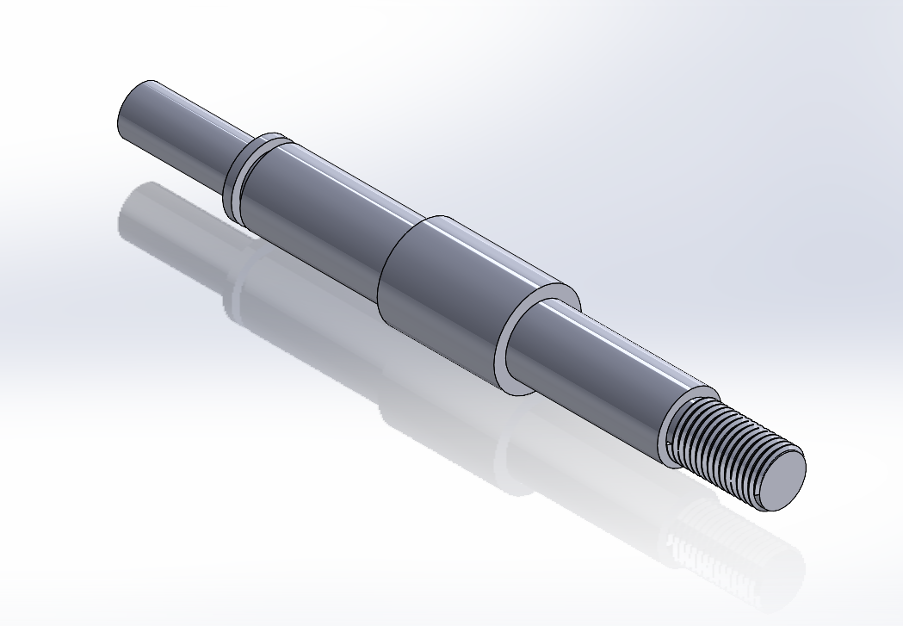

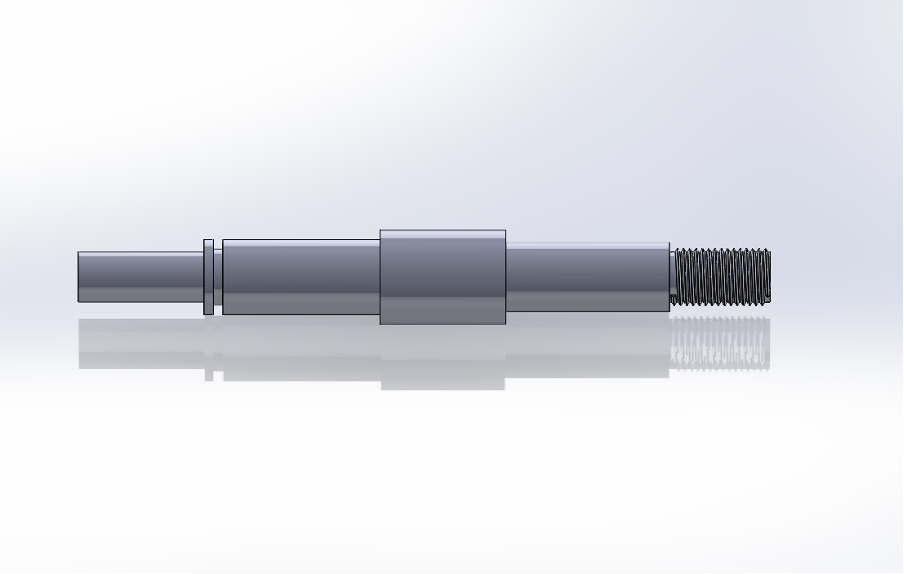

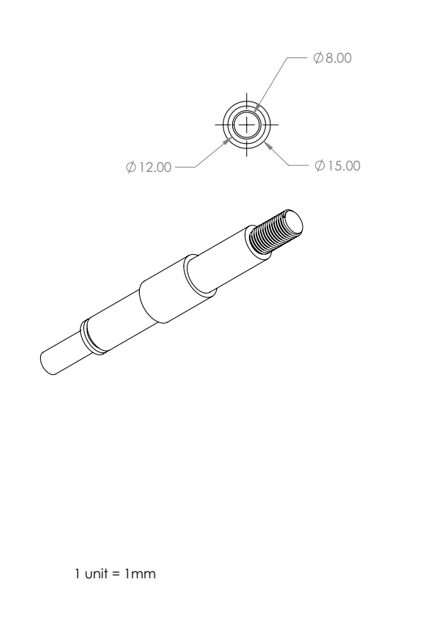

Motor Coupler Shaft

This is a Mild Steel Shaft for a Robot Wheel. It is used with Bearing Housing for smooth power transmission between the motor and the HD wheel of your robot.

Download Part Drawing

General Safety & Precautions

- Always wear safety goggles and a face shield while operating the lathe.

- Tie back long hair and avoid loose clothing or jewelry.

- Ensure the workpiece is tightly secured in the chuck before starting.

- Verify the tool is properly aligned and tightly clamped.

- Never leave the machine running unattended.

- Keep hands away from the rotating chuck and tools during operation.

- Use the correct cutting speed, feed rate, and depth of cut to avoid tool breakage or accidents.

- Clean chips with a brush or hook — never with hands.

- Always stop the machine before making measurements or adjustments.

Process Sheet

Step-0: Material Required

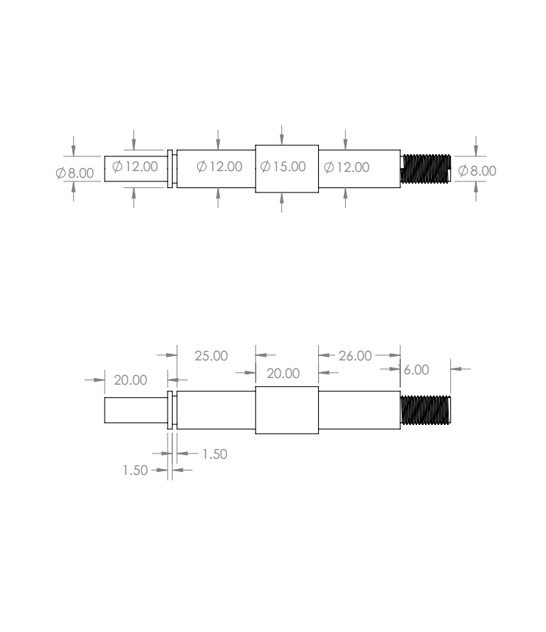

- Workpiece: Mild Steel Cylindrical Rod – dia. 20 mm, length 150 mm

- Tools Required:

- Single Point Cutting Tool (HSS/Carbide insert)

- Grooving Tool

- M8 Threading Die

Step-1: Machine and Workpiece Setup

- Operation: Mount and center the workpiece on the lathe

- Machine/Tool Required: Lathe

- Operation Time: 15 minutes

Step-2: Facing the Stock Piece

- Operation: Face the end surface of the rod

- Machine/Tool Required: Lathe / Single Point Cutting Tool

- Operation Time: 10 minutes

Step-3: Straight Turning – dia. 20 mm to dia. 15 mm

- Operation: Reduce diameter from dia. 20 mm to dia. 15 mm

- Machine/Tool Required: Lathe / Single Point Cutting Tool

- Operation Time: 30 minutes

Step-4: Straight Turning – dia. 15 mm to dia. 8 mm

- Length: 0 mm to 20 mm

- Machine/Tool Required: Lathe / Single Point Cutting Tool

- Operation Time: 20 minutes

Step-5: Straight Turning – dia. 15 mm to dia. 12 mm

- Length: 20 mm to 48 mm

- Machine/Tool Required: Lathe / Single Point Cutting Tool

- Operation Time: 15 minutes

Step-6: Groove Cutting – dia. 12 mm to dia. 9 mm

- Length: 21.5 mm to 23 mm

- Machine/Tool Required: Lathe / Grooving Tool

- Operation Time: 15 minutes

Step-7: Straight Turning – dia. 15 mm to dia. 11 mm

- Length: 68 mm to 94 mm

- Machine/Tool Required: Lathe / Single Point Cutting Tool

- Operation Time: 15 minutes

Step-8: Straight Turning – dia. 15 mm to dia. 8 mm (approx.)

- Length: 94 mm to 110 mm

- Machine/Tool Required: Lathe / Single Point Cutting Tool

- Operation Time: 30 minutes

Step-9: Threading – M8 External Threads

- Operation: Cut M8 threads

- Machine/Tool Required: Lathe / M8 Threading Die

- Operation Time: 20 minutes

Learning Outcomes

- Proper use of marking and hand tools

- Workpiece alignment

- How the feed and depth of cut are provided

- Facing

- Turning

- Step turning

- Grooving

- Threading