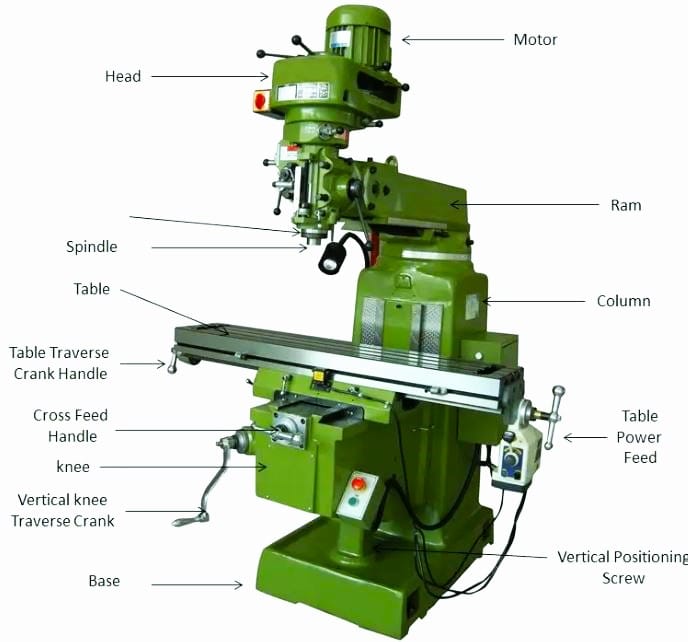

Vertical Milling Machine(VMC)

Basic Introduction

A vertical milling machine positions its spindle vertically above the workpiece, allowing the milling cutter to move up and down while the workpiece moves on the X, Y, and Z axes. The machine is essential for machining flat surfaces, slots, grooves, pockets, and complex contours in metal and other hard materials, with varying degrees of precision and automation, from manual knee mills to fully automated CNC machining centres.

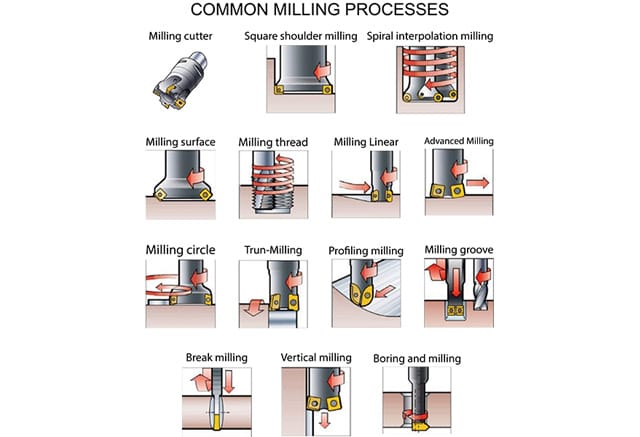

Main Operations Performed

Plain/Slab Milling

Plain milling uses a cylindrical cutter to machine flat surfaces parallel to the worktable. The cutter rotates at high speed while the workpiece is fed in a straight line, producing flat, fine-finished surfaces ideal for large base plates and components.

End Milling

End milling is a fundamental process using an end mill to machine flat surfaces, contours, slots, and pockets on the workpiece. The end mill, with cutting edges on its end and sides, rotates in the spindle while the workpiece moves in the X, Y, and/or Z directions under CNC control. End milling is highly versatile and can produce a variety of profiles, including square shoulders and intricate shapes, with excellent surface finish.

Face Milling

Face milling produces smooth, flat surfaces perpendicular to the spindle axis. A face mill cutter with multiple carbide inserts rotates at high speed, and the workpiece is fed across the table. This operation is perfect for squaring stock and finishing large top surfaces.

Profile Milling

Profile milling machines the outline of a part, cutting along complex contours. The vertical milling machine, with its precise CNC control, easily reproduces intricate profiles—such as those found in dies, molds, and aerospace components—using end mills or ball-nose cutters.

Slot Milling

Slot milling cuts narrow grooves or channels into the workpiece using end mills or slot drills. This operation is essential for creating keyways, splines, and other features requiring precise width and depth, all repeatedly accurate thanks to CNC automation.

Pocket Milling

Pocket milling removes material to create recesses or cavities within the workpiece. The machine sequentially mills the pocket’s perimeter and then clears the interior, often using helical interpolation for efficiency. This is widely used for housing electronic components or mechanical parts.

Drilling

The vertical milling machine can perform high-precision drilling operations with various drill bits. The CNC control ensures hole positions are accurate and repeatable, even for large batches. Peck drilling cycles are standard for deep holes.

Boring

Boring enlarges or finishes pre-drilled holes to precise diameters and surface finishes. The machine uses boring bars or special boring heads, achieving tight tolerances and excellent surface quality for bearing seats and other critical bores.

Tapping

Tapping cuts internal threads in pre-drilled holes. The vertical milling machine rigid spindle and synchronized feed allow for both rigid tapping (synchronized Z-axis and spindle) and floating tapping, ensuring accurate threads in tough materials.

3D Contouring

With advanced CNC programming, the machine can execute complex 3D milling operations, sculpting intricate shapes and freeform surfaces. This is indispensable for mold, die, and turbine blade manufacturing.

Reaming

Reaming improves the finish and accuracy of drilled or bored holes. The machine feeds a reamer into the hole at a controlled speed, ensuring dimensional precision for critical assemblies.

Chamfering/Edge Milling

Chamfering tools or ball-nose end mills are used to bevel edges, remove burrs, and prepare parts for assembly or aesthetic finishing.