Sheet Metal Working

Booking Time: 3 hours

Max CMF Points Earned: 400 Pts.

Facility to Book : Sheet Metal Workbench

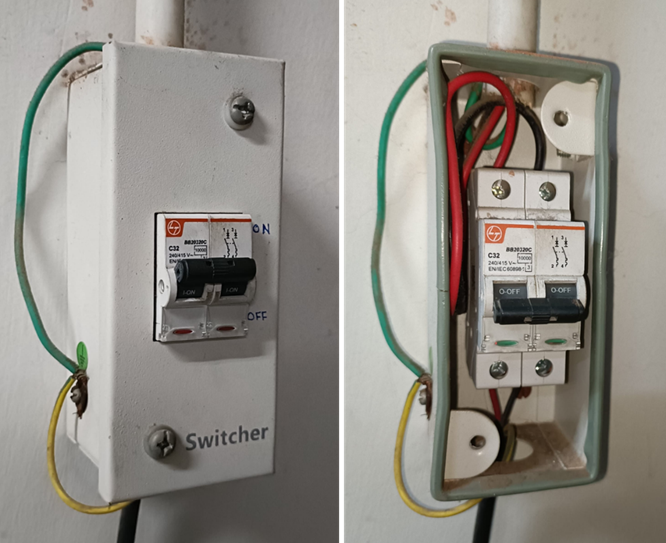

MCB Enclosure Box

MCB enclosure box is a compact sheet metal box designed to securely house and protect electrical MCBs used in homes, offices, factories, and commercial buildings. Its main purpose is to ensure safe and efficient distribution of electricity while shielding the circuit breakers from dust, moisture, and accidental contact. These boxes are typically made from durable materials like metal or high-grade plastic and come in various sizes to accommodate different circuit configurations.

Skills required:

Shearing Machine / Snip Tool

Learn a basic introduction about Shearing Machine or Snip Tool before performing any operation.

Mechanical Press

Learn a basic introduction about Mechanical Press before performing any operation.

Drill Machine

Learn a basic introduction about Drill Machine before performing any operation.

Bending Machine

Learn a basic introduction about Bending Machine before performing any operation.

Spot Welding Machine / Riveting

Learn a basic introduction about Spot Welding Machine or Rivet Gun before performing any operation.

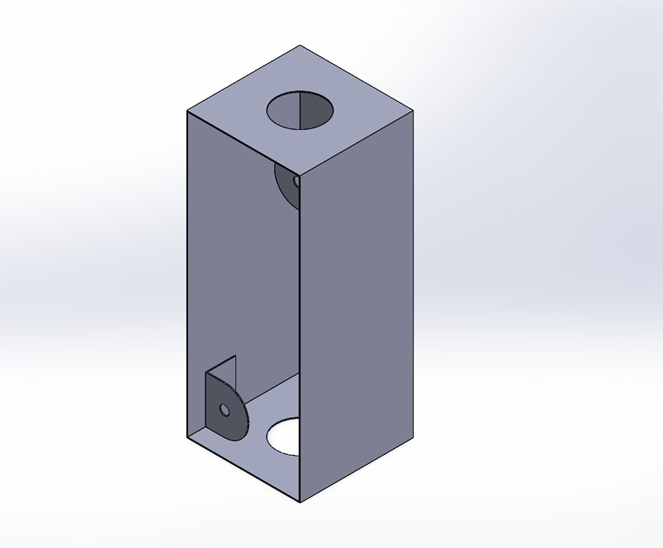

Part -1 (Lower box)

Max CMF Points Earned: 230

Total Time Estimate: 105 minutes

Steps to be followed for the preparation of the lower box:

Step-0: Material and Tools Required

- Aluminium Sheet (1 mm thick) – 270 mm × 180 mm

- Tools/Equipment: Scale, scriber, snip tool, shearing machine, bending machine, manual/mechanical press machine, drill machine, laser welding

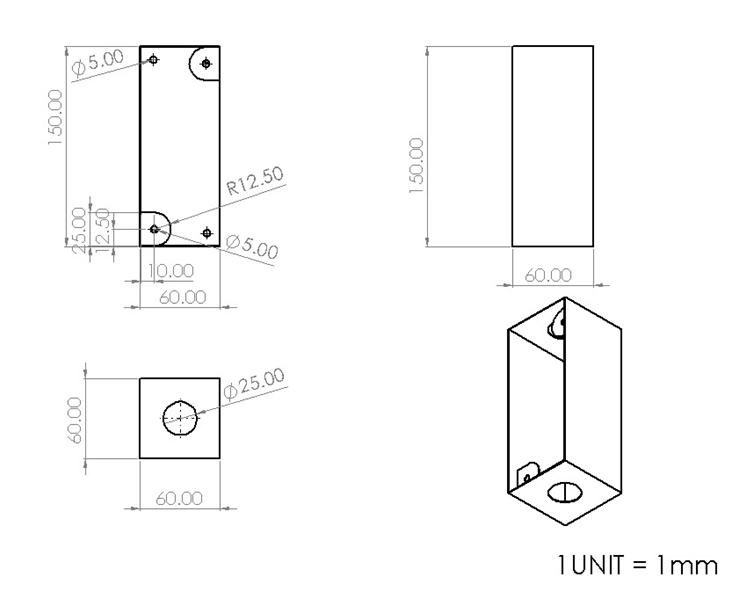

Step-1: Marking and cutting

- Mark layout as per the dimensions given in the part drawing for the cutting operation. Thereafter, cut the part using a snip tool as shown in the sketch below.

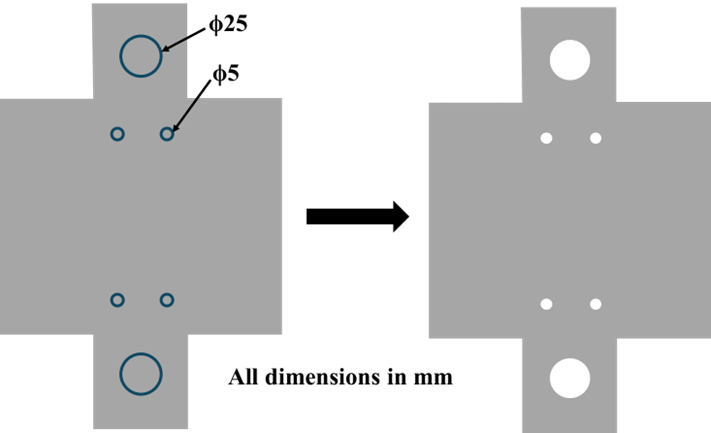

Step-2: Marking and creating holes

Mark the layout as per the dimensions given in the part drawing for making holes. Thereafter, cut two holes of 25 mm diameter using a circular snip tool and drill four screw holes of 5 mm diameter using a drill machine. Follow the sketch given below

Step-3: Bending

- Bend the sheet as per the drawing using a bending machine to make the basic enclosure shape as shown in the picture below.

Step-4: Laser welding

- Weld all four corner edges using a laser welding machine for better strength.

Step-5: L-Shaped Component Preparation

- Prepare two L-shaped support/side pieces using cutting, bending, and drilling holes as per the drawing. The prepared L-shape component is shown below.

Step-6: Joining the L-shape with the Box Body

- Assemble L-shape brackets to the box base (refer part drawing) using riveting or laser welding.

Step-7: Finishing

- Finish all the edges and corners to remove sharpness and burr using a file.

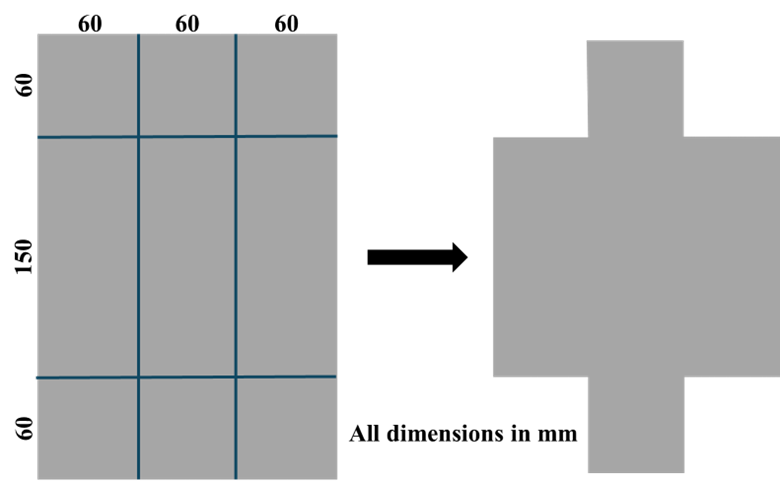

Part -2 (Upper box)

Max CMF Points Earned: 100

Total Time Estimate: 75 minutes

Steps to be followed for the preparation of the upper box:

Step-0: Material and Tools Required

- Aluminium Sheet (1 mm thick) – 180 mm × 90 mm

- Tools/Equipment: Scale, scriber, snip tool, shearing machine, bending machine, manual/mechanical press, drill machine

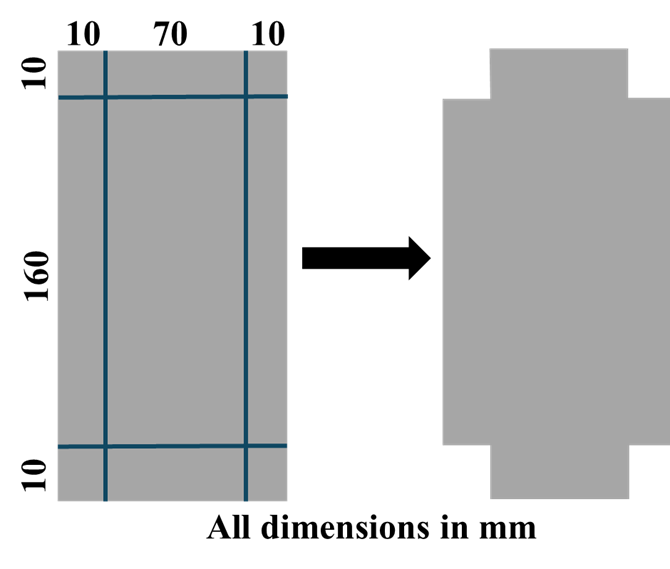

Step-1: Marking and cutting

- Mark layout as per the dimensions given in the part drawing for the cutting operation. Thereafter, cut the part using a snip tool as shown in the sketch below.

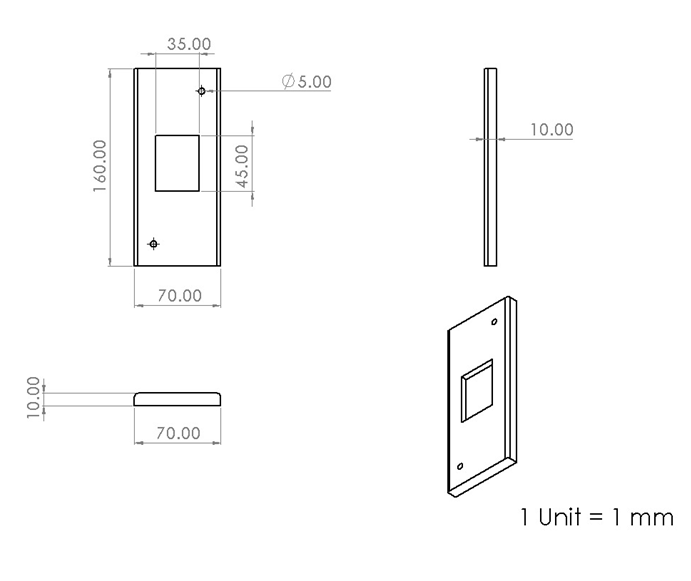

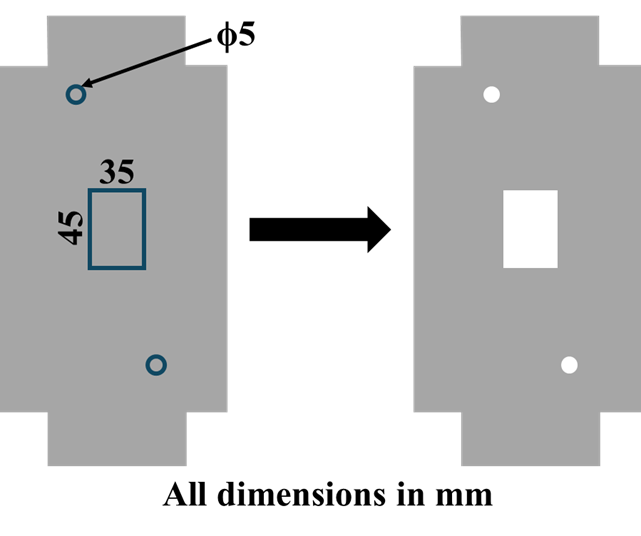

Step-2: Marking and making a slot, and drilling holes

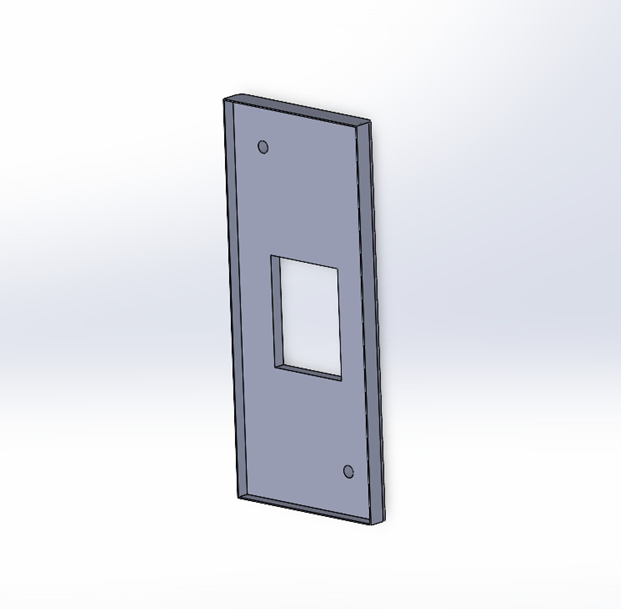

- Mark the layout as per the dimensions given in the part drawing for the making slot and drilling holes. Thereafter, cut a rectangular slot of 45×35 mm using a circular snip tool and drill two screw holes of 5 mm diameter using a drill machine. Follow the sketch given below.

Step-3: Bending

- Bend the sheet as per the drawing using a bending machine to make the basic enclosure shape as shown in the picture below.

Step-4: Finishing

· Finish all the edges and corners to remove sharpness and burr using a file.\

Learning outcomes

- Proper use of measurement and marking

- Cutting

- Cutting holes

- Cutting slot

- Drilling

- Bending

- Finishing

- Knowledge of different joints in sheet metal