Milling on Vertical Milling Machine(VMC)

VMC Booking Time: 3 Hrs

Max CMF Points Earned: 400 Pts.

Facility to Book : MNTR Milling Machine

Vertical Milling Machine

Learn basic introduction about the Vertical Milling Machine (VMC) before performing any operation.

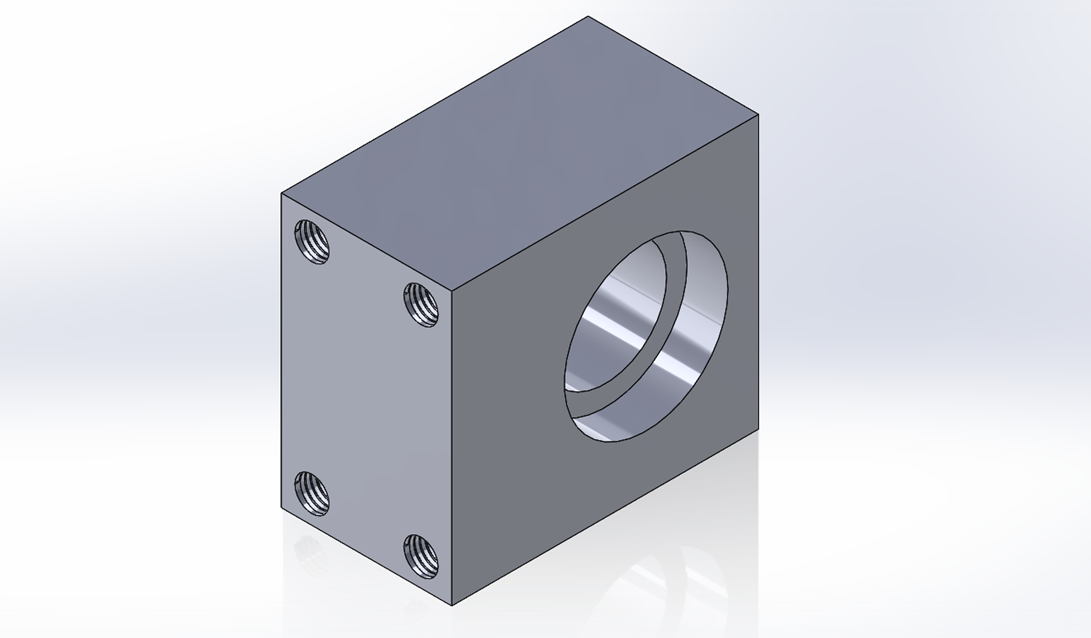

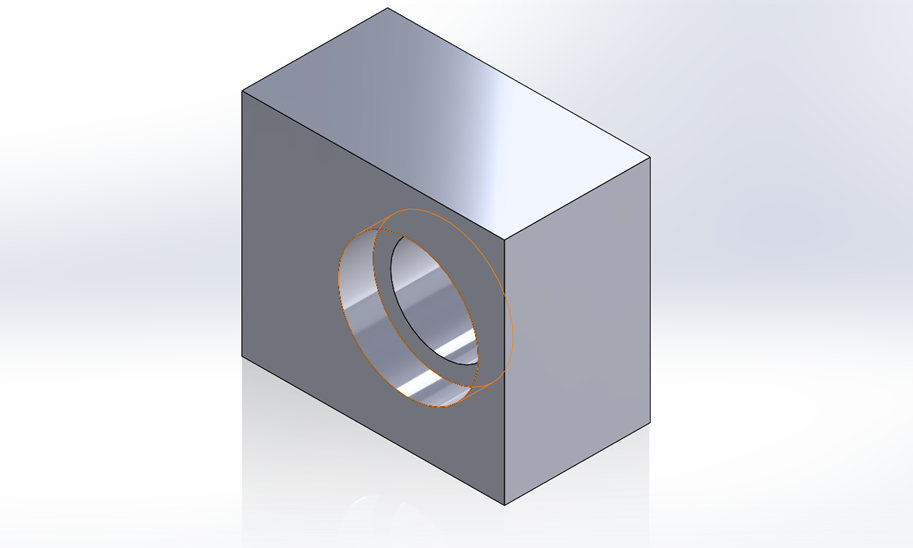

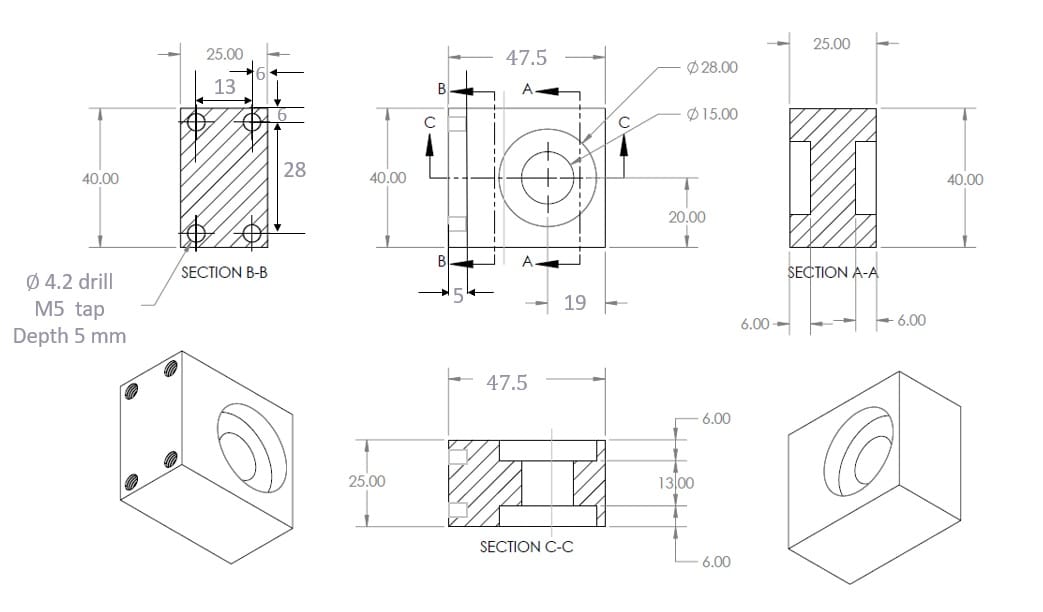

Bearing Housing

The bearing housing is a mechanical structure designed to support and position bearings, which ensure accurate alignment, load distribution and rigid mounting in rotating machinery.

Download Part Drawing

General Safety & Precautions

- Always wear safety goggles and ear protection while operating the VMC.

- Securely clamp the workpiece before beginning any operation.

- Never touch rotating parts or cutting tools while the machine is running.

- Keep the work area clean and free from oil and chips.

- Use appropriate cutting fluid to avoid overheating.

- Check tool alignment and offsets before starting operations.

- Do not leave the machine unattended while in operation.

- Use proper speeds and feeds to prevent tool breakage.

Step-0: Material & Tools Required

- Workpiece: Mild Steel or Aluminum Block (as per project specification)

- Tools Required:

- Face Mill Cutter (dia. 10 mm)

- End Mill Cutter (dia. 10 mm)

- Twist Drills (dia. 4.2 mm, 8 mm, 15 mm, 18 mm)

- M5 Tap

- VMC or Vertical Milling Machine

- Tapping Tools

Step-1: Clamp Workpiece and Set Machine

- Operation: Secure the block on the VMC bed and set up a zero reference

- Tool Required: Face Mill Cutter (dia. 10 mm), End Mill Cutter (dia. 10 mm), Drill Press with 8 mm drill bit, Drill Press with 15 mm drill bit, Drill Press with 4.2 mm drill bit

- Time: 20 minutes

Step-2: Face Milling – Top Surface

- Operation: Perform facing to level the top surface

- Tool Required: Face Mill Cutter (dia. 10 mm)

- Time: 10 minutes

Step-3: End Milling – Side Surfaces

- Operation: Finish the side faces of the block

- Tool Required: End Mill Cutter (dia. 10 mm)

- Time: 20 minutes

Step-4: Face Milling – Bottom Surface

- Operation: Face the underside of the block

- Tool Required: Face Mill Cutter (dia. 10 mm)

- Time: 10 minutes

Step-5: Drill Pilot Hole – dia. 8 mm

- Operation: Drill a pilot hole for larger through holes

- Tool Required: VMC / Drill Press with 8 mm drill bit

- Time: 10 minutes

Step-6: Drill Through Hole – dia. 12 mm

- Operation: Enlarge the hole to 15 mm diameter

- Tool Required: VMC / Drill Press with 15 mm drill bit

- Time: 10 minutes

Step-7: Drill Through Hole – dia. 15 mm

- Operation: Further enlarge the hole to 18 mm diameter

- Tool Required: VMC / Drill Press with 10 mm drill bit

- Time: 10 minutes

Step-8: End Milling – Counterbore dia. 28 mm

- Operation: Create a counterbore with dia. 28 mm

- Tool Required: End Mill Cutter – dia. 10 mm

- Time: 10 minutes

Step-9: Drill Pilot Hole – dia. 8 mm (Opposite Face)

- Operation: Drill pilot hole on the opposite side

- Tool Required: VMC / Drill Press with 8 mm drill bit

- Time: 10 minutes

Step-10: Drill Through Hole – dia. 12 mm (Opposite Face)

- Operation: Drill final diameter through the block

- Tool Required: VMC / Drill Press with 18 mm drill bit

- Time: 10 minutes

Step-11: End Milling – Counterbore dia. 28 mm (Opposite Face)

- Operation: Create a counterbore on opposite side

- Tool Required: End Mill Cutter – dia. 24 mm

- Time: 10 minutes

Step-12: Drill Tap Holes – dia. 4.2 mm for M5 (4 holes)

- Operation: Drill holes in preparation for internal M5 threading

- Tool Required: VMC / Drill Press with 4.2 mm drill bit

- Time: 10 minutes

Step-13: Tapping – Internal M5 Thread (4 holes)

- Operation: Tap M5 internal thread

- Tool Required: M5 Tap & Tapping Machine

- Time: 10 minutes

Learning outcome:

- Proper use of marking and hand tools

- Workpiece alignment

- How to use VMC?

- Face milling

- End milling

- Drilling and tapping