Mechanical Press Machine

A mechanical press machine is a power-driven machine used to shape or cut materials by applying mechanical force. It converts rotational motion into linear motion using mechanical components such as flywheels, crankshafts, gears, or cams. Mechanical presses are commonly used in sheet metal operations such as punching, blanking, bending, and forming.

Basic Components

Flywheel—Stores kinetic energy and provides energy to the press during operation.

Clutch & Brake System – Engages or disengages the flywheel from the crank mechanism and stops the press when required.

Crankshaft / Eccentric Shaft – Converts rotary motion from the flywheel into reciprocating motion.

Ram/Slide—The vertically moving part that applies the force to the workpiece.

Bed/Frame – Supports the die and holds the workpiece in place.

Motor – Drives the flywheel and crank mechanism.

Die Set – The tooling mounted on the bed and ram used to shape the material.

Working Principle of a Mechanical Press Machine

The mechanical press machine works by transforming rotational motion into linear force through mechanical linkages. The key principle lies in storing energy in a flywheel and releasing it through a crank mechanism that drives the ram.

Working Steps

- Flywheel Rotation Begins

The electric motor rotates the flywheel continuously. The flywheel accumulates kinetic energy during this rotation.

- Clutch Engages

When the operator initiates the press cycle, the clutch connects the flywheel to the crankshaft, allowing energy transfer.

- Rotational Motion Converts to Linear Motion

The crankshaft or eccentric shaft converts the flywheel’s rotational motion into reciprocating motion of the ram.

- Ram Applies Force

The ram (slide) descends at high speed and exerts a powerful force on the material placed on the die, performing operations like punching, blanking, or forming.

- Ram Retracts

After the stroke, the brake stops the flywheel momentarily, and the ram returns to its top position, ready for the next cycle.

Key Advantages of Mechanical Working Principle

- High-Speed Operation

Ideal for mass production due to faster cycle times compared to hydraulic presses.

- Energy Efficient at High Volume

Once the flywheel is in motion, energy usage per stroke is lower, making it efficient for repetitive operations.

- Consistent Stroke and Accuracy

Provides precise and repeatable stroke depth, suitable for operations requiring tight tolerances.

- Simpler Maintenance and Setup

Mechanical systems are generally easier to maintain and set up for standard operations.

- Cost-Effective for Medium to Thin Materials

Well-suited for stamping, blanking, and punching sheet metal parts in large quantities.

Process of a Mechanical Press Machine

A mechanical press uses rotational energy stored in a flywheel and converts it into linear force using a crank mechanism. This enables fast, repetitive forming or cutting operations on sheet metal.

- Preparation

Workpiece Setup:Place the sheet metal or part on the die located on the press bed.

Die and Tooling Positioning:Secure the upper and lower dies according to the operation (e.g., punching, blanking, bending).

Adjustments:Set stroke length, shut height, and ram position as per workpiece requirements.

- Power On

Start the Electric Motor:The motor begins to rotate the flywheel, which stores kinetic energy.

System Readiness:Ensure clutch, brake, and safety systems are functional before operation.

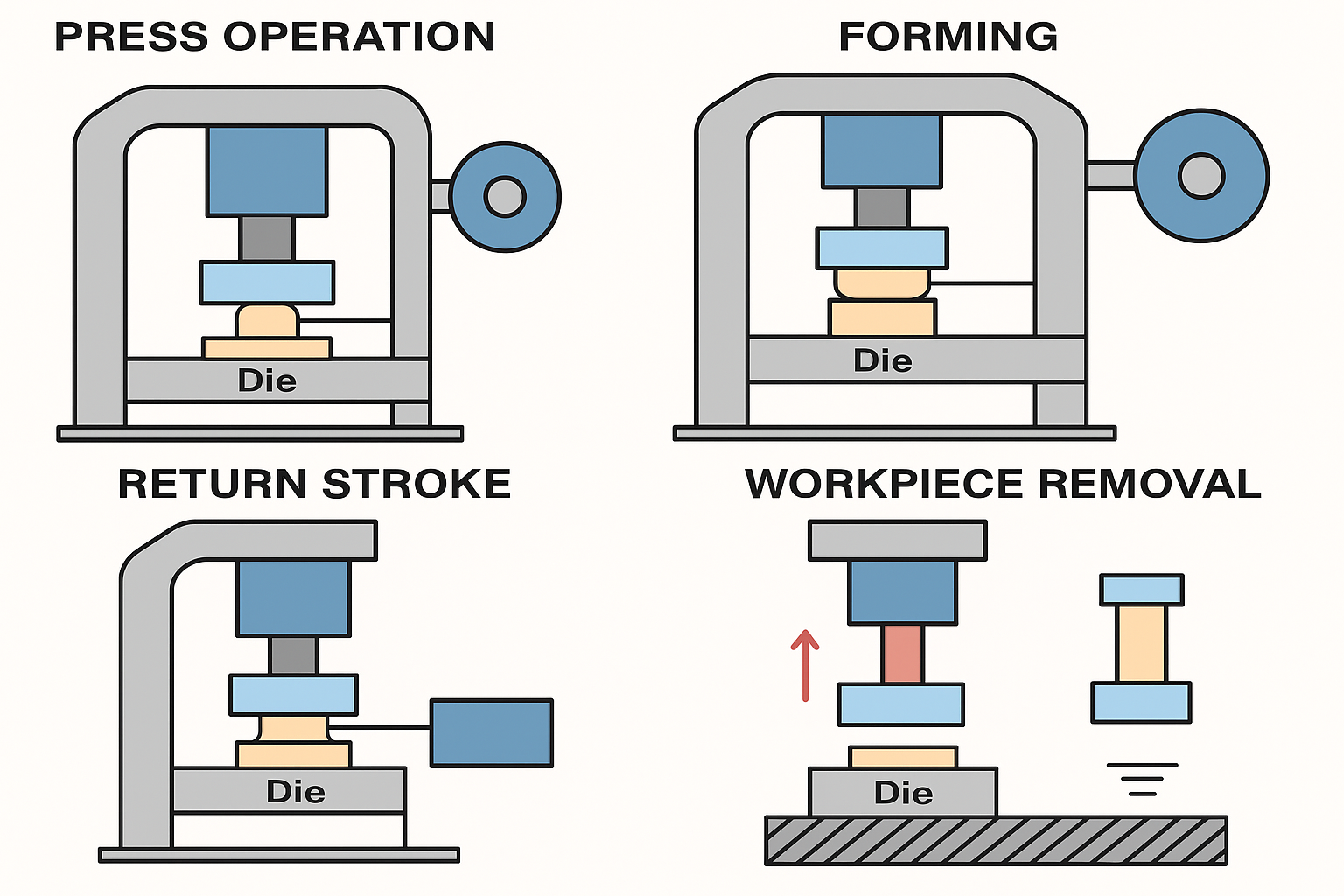

3. Press Operation

Clutch Engagement:The operator uses a foot pedal or control switch to engage the clutch, connecting the flywheel to the crankshaft.

Crank Mechanism Activated:The crank converts rotary motion into vertical motion, moving the ram downward.

- Pressing / Forming

Ram Action:The ram applies a powerful downward force on the workpiece via the die.

Common Operations:

· Punching

· Blanking

· Coining

· Bending

· Embossing

- Return Stroke

Ram Returns Automatically:After reaching the bottom dead center, the crankshaft continues its rotation, bringing the ram back up.

Brake Engages (If Required):Stops the ram at the top position if continuous operation is not selected.

6. Workpiece Removal

Remove the Finished Part:Once the ram has retracted, the pressed or cut workpiece can be removed.

Reload for Next Cycle:Place the next blank or sheet for repeat operations.

Advantages of Mechanical Press Machine

- High-Speed Operation:

Mechanical presses operate at faster cycle rates, making them ideal for mass production and high-volume manufacturing. - Consistent Stroke and Accuracy:

Delivers precise and repeatable strokes, essential for operations requiring tight tolerances (like punching and blanking). - Energy Efficient in Continuous Use:

Once the flywheel is in motion, it delivers energy efficiently with lower power usage per stroke in high-speed operations. - Lower Operating Costs:

Mechanical systems typically require less hydraulic oil, cooling, or complex fluid handling, reducing recurring costs. - Simpler Mechanical Design:

Fewer fluid-related components mean easier maintenance and troubleshooting. - Compact for High-Speed Jobs:

Mechanical presses are often more compact when designed for high-speed jobs, especially in stamping lines. - Immediate Ram Movement:

No lag in stroke response—ram begins moving instantly upon clutch engagement, enabling better synchronization in automated systems.

Disadvantages of Mechanical Press Machine

- Fixed Stroke Length:

Most mechanical presses operate with preset stroke lengths, limiting flexibility for varying workpiece thicknesses. - Less Control over Force:

The force output depends on the flywheel energy and crank position—not adjustable mid-cycle like in hydraulic systems. - Safety Risk if Not Guarded Well:

High-speed strokes can be hazardous without proper guards, sensors, or light curtains. - Shock Loads and Vibration:

Rapid energy release can generate significant shock and noise, affecting machine life and requiring vibration damping. - More Wear and Tear:

Mechanical parts like bearings, gears, and clutches are prone to wear in continuous operation, needing regular checks.

Limitations of Mechanical Press Machine

- Not Ideal for Variable Load Jobs:

Mechanical presses are less suited for processes that require force variation during stroke, like deep drawing. - No Force Feedback Control:

Unlike hydraulic presses, they cannot modulate or sense force in real-time, affecting part quality in sensitive operations. - Limited Ton Range in Compact Sizes:

To achieve very high forces, mechanical presses tend to become large and bulky, unlike compact hydraulic designs. - Requires Flywheel Run-Up Time:

Startup energy demand is high as the flywheel must reach operational speed before pressing can begin. - Retrofitting is Complex:

Modifying or automating older mechanical presses is more challenging compared to programmable hydraulic systems.