Manual Shearing Machine

A manual shearing machine is a hand-operated device used to cut sheet metal or other materials into specific shapes and sizes. It is commonly used in workshops and fabrication units where simple cutting tasks are needed without the use of power or automation. These machines are cost-effective, durable, and easy to maintain. They're ideal for small-scale production and maintenance tasks.

Working Principle of Manual Shearing Machine

The manual shearing machine operates on the mechanical principle of shearing, similar to how scissors work. It uses a pair of sharp blades—one fixed and one movable—to cut sheet metal or other thin materials.

How It Works:

1. Material Placement: The sheet metal is placed between the upper (moving) blade and the lower (fixed) blade on the machine bed.

2. Manual Force Applied: The operator pulls or pushes a lever or handle, which moves the upper blade downward.

3. Shearing Action: As the upper blade descends, it moves past the lower blade with a small clearance between them. This creates a shear force that cuts the material along a straight line.

4. Cut Completion: Once the full stroke is complete, the material is cleanly sheared, and the handle is returned to its original position for the next cut.

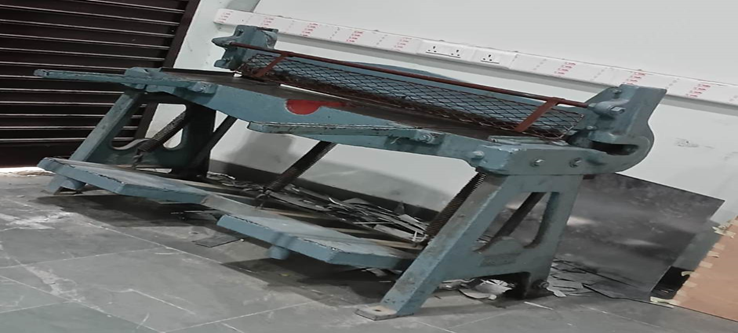

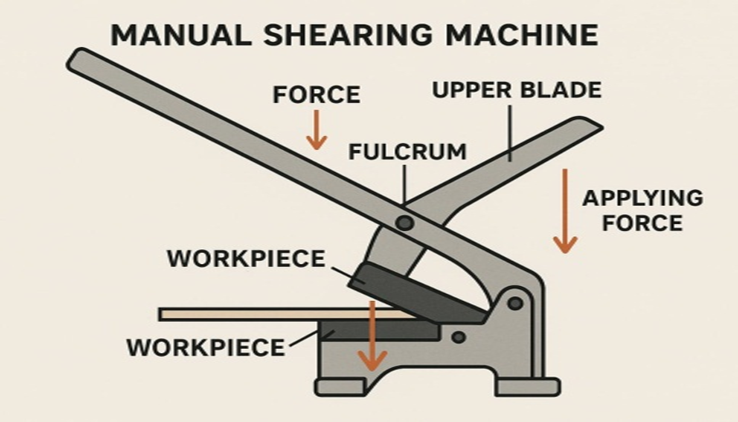

Figure 1: Manual Shearing Machine

Key Features of the Working Principle:

Relies entirely on manual force, no electricity or hydraulics involved.

The clearance between blades and sharpness are critical for a clean cut.

Designed primarily for straight cuts on thin to moderately thick sheets.

The main components of a manual shearing machine are:

1. Handle / Lever

Provides the manual force needed to operate the machine.

The longer the handle, the more leverage and cutting power.

2. Pivot (Fulcrum Point)

The rotating point where the lever moves.

Converts the applied force into a downward motion of the upper blade.

3. Upper Blade

Mounted on the movable arm.

Moves downward to shear the material.

4. Lower Blade

Fixed in position.

Works together with the upper blade to create a scissor-like cutting action.

5. Base / Frame

Supports the entire machine.

Provides stability and houses the lower blade.

6. Worktable / Bed

Flat surface where the workpiece is placed for cutting.

May include guides or stops for accurate positioning.

7. Blade Guard (optional in some designs)

Provides safety by covering the blades when not in use.

8. Hold-down Clamps (sometimes included)

Hold the workpiece securely to prevent movement during cutting.

Process:

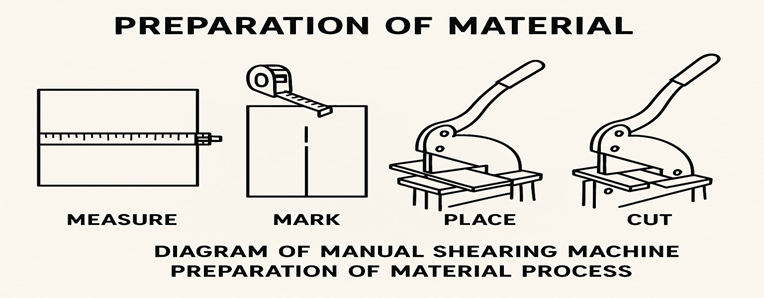

1. Preparation of Material

Place the metal sheet (or workpiece) on the worktable.

Adjust position using guides or markings for accurate cutting.

Figure 2: Material Preparation in Manual Shearing Machine

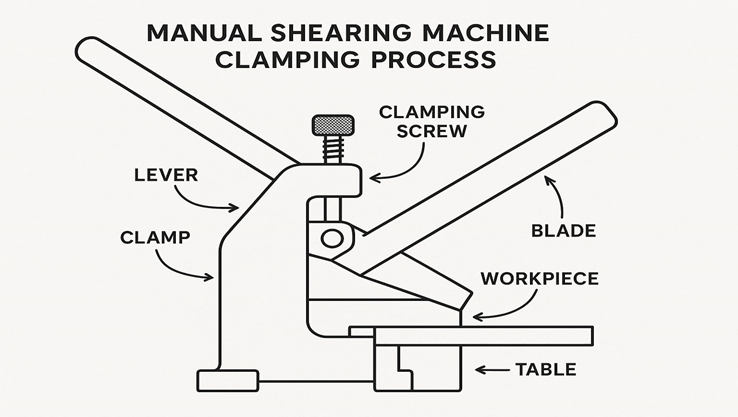

Secure the workpiece using hold-down clamps to prevent shifting.

Figure 3: Clamping Process in Manual Shearing Machine

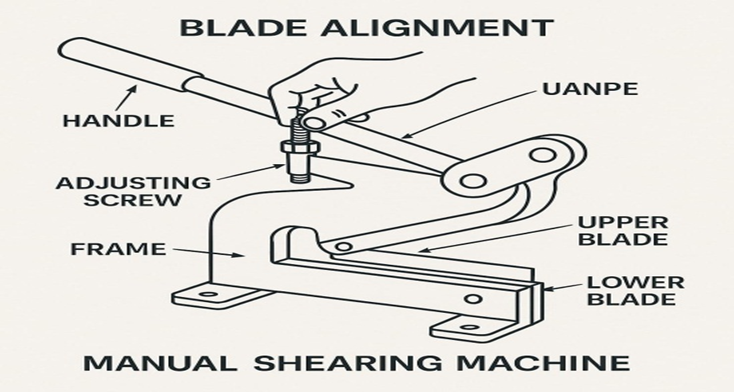

2. Aligning the Blade

Position the part of the sheet where the cut is desired directly under the upper blade.

Figure 4: Alignment of Manual Shearing Machine Blade

3. Applying Force

Pull the handle or lever downward.

The lever multiplies the applied force and moves the upper blade downward.

Figure 5: Apply Force on Manual Shearing Machine

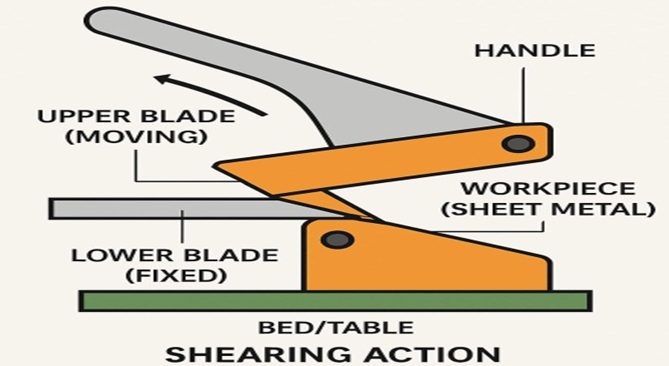

4. Shearing Action

The upper blade moves down and presses the sheet against the lower blade.

The material is sheared through the scissor-like action.

Figure 6: Shearing action on Manual Shearing Machine

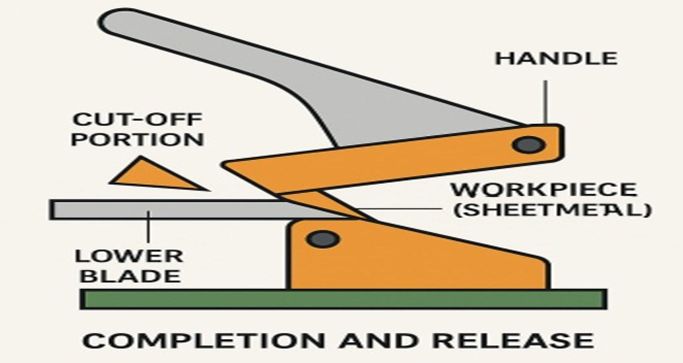

5. Completion and Release

After the cut, release the handle.

Remove the cut piece and prepare for the next operation. Fixed in position.

Works together with the upper blade to create a scissor-like cutting action.

Fig 7: Shearing operation Completion and Release of Work Piece

Capacity

The capacity of a manual shearing machine depends on the machine's size and construction but typically includes:

Sheet Thickness: Up to 2–6 mm mild steel (depending on the model)

Sheet Width: Typically 500 mm to 2000 mm

Material: Mild steel, aluminum, copper sheets, plastic sheets (non-ferrous materials)

Note: Exact capacity depends on blade quality, leverage, and operator strength.

Applications

Manual shearing machines are used in small-scale and medium industries for cutting sheet metal. Common applications include:

Sheet metal fabrication

Cutting blanks for bending or forming

HVAC ductwork fabrication

Automotive body parts

Roofing and cladding works

Educational/training workshops

Advantages

Low Cost: Inexpensive to purchase and maintain.

No Power Required: Operates manually — ideal for areas without electricity.

Simple Operation: Easy to use with minimal training.

Low Maintenance: Fewer moving parts compared to motorized machines. Portable: Can be moved easily in smaller workshops.

Disadvantages

Low Productivity: Slower than hydraulic or motorized shears.

Limited Thickness: Can only cut thin sheets effectively.

Manual Labor Intensive: Operator fatigue for repetitive tasks.

Limited Accuracy: Less precise than CNC or powered shears.

Not Suitable for Mass Production: Designed for small batch or prototyping work.

Limitations

Cannot cut hard materials like stainless steel or thick mild steel.

Fixed blade gap: May not be adjustable for different materials or thicknesses.

No automation: All cuts are manual — cannot be integrated into automated production lines.

Operator skill-dependent: Quality and consistency depend on the operator’s experience.

Safety Risk: Manual operation may pose safety risks if not handled properly

Materials That Can Be Cut Using a Manual Shearing Machine

Manual shearing machines are designed to cut sheet materials — mostly ductile, soft to medium-hard metals, and some non-metals. Here's a list of common materials:

Metals (Ferrous and Non-Ferrous)

|

Sr.No. |

Material |

Notes |

|

1 |

Mild Steel |

Commonly used ,usually up to 2-3 mm

thickness |

|

2 |

Aluminum |

Soft and easy to shear |

|

3 |

Copper |

Soft, ductile and easy to cut |

|

4 |

Brass |

Easy to shear, used in decorative and

electrical applications |

|

5 |

Galvanized steel |

Common in HVAC and ductwork |

|

6 |

Tin/Sheet Tinplate |

Soft, often used for containers |

|

7 |

Lead Sheet |

Very soft and easy to cut |

|

8 |

Zinc Sheet |

Can be cut in roofing and decorative

work |

High-carbon steel, stainless steel, and hardened alloys are generally not suitable due to high hardness and wear on blades.

Non-Metallic Materials (Limited Use)

|

Sr.No. |

Material |

Notes |

|

1 |

Plastic Sheets(PVC,Acrylic) |

Only thin, rigid sheets-risk of

cracking or chipping |

|

2 |

Rubber Sheets |

Thin sheets only-not ideal due to

elasticity |

|

3 |

Fiber Sheet(FRP,Cardboard) |

Possible with some models,but not

ideal for repeated use |

|

4 |

Laminates |

Like Formica-can be cut with proper

care |

Important Considerations

Always check the material thickness, hardness, and machine specifications.

Overloading or using inappropriate materials can damage blades or injure the operator.

Use sharp, clean blades and maintain proper blade clearance for clean cuts