Manual Shearing Machine

A manual shearing machine is used to cut sheet metal into specific shapes and sizes. Just like the scissors used to cut paper, this machine is like a heavy-duty scissor designed for cutting thin metal sheets. It helps prepare the basic parts that will later be bent, drilled, or assembled. These machines are cost-effective, durable, and easy to maintain. They're ideal for small-scale production and maintenance tasks.

For smaller cuts or when the design is simple, we can also use snip tools (which are hand-operated metal cutters) to make precise cuts by hand.

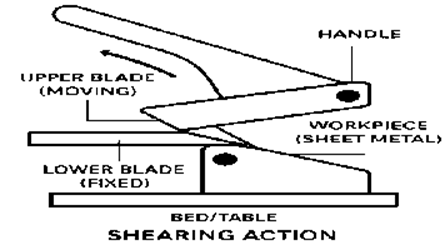

How it works?

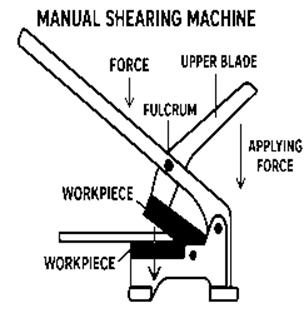

Material Placement: The shearing machine has two sharp blades: The lower one is fixed at the bottom and the upper one moves down when we apply force (manually or using a foot pedal/lever) and the sheet metal is placed in between them.

Shearing action: The operator pulls or pushes a lever or handle, which moves the upper blade downward. As the upper blade descends, moving past the lower blade with a small clearance between them, it creates a shear force that cuts the material along a straight line.

For manual snip tools, you use your hand strength to squeeze the handles, and the blades cut the sheet like scissors.

Cut Completion: Once the full stroke is complete, the material is cleanly sheared, and the handle is returned to its original position for the next cut.

The main components of a manual shearing machine are:

1. Handle / Lever

· Provides the manual force needed to operate the machine.

· The longer the handle, the more leverage and cutting power.

2. Pivot (Fulcrum Point)

· The rotating point where the lever moves.

· Converts the applied force into a downward motion of the upper blade.

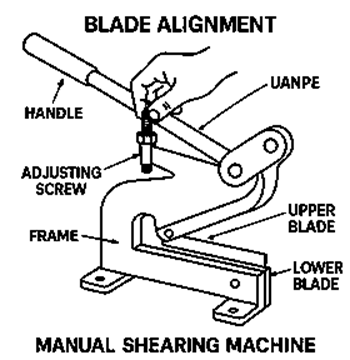

3. Upper Blade

· Mounted on the movable arm.

· Moves downward to shear the material.

4. Lower Blade

· Fixed in position.

· Works together with the upper blade to create a scissor-like cutting action.

5. Base / Frame

· Supports the entire machine.

· Provides stability and houses the lower blade.

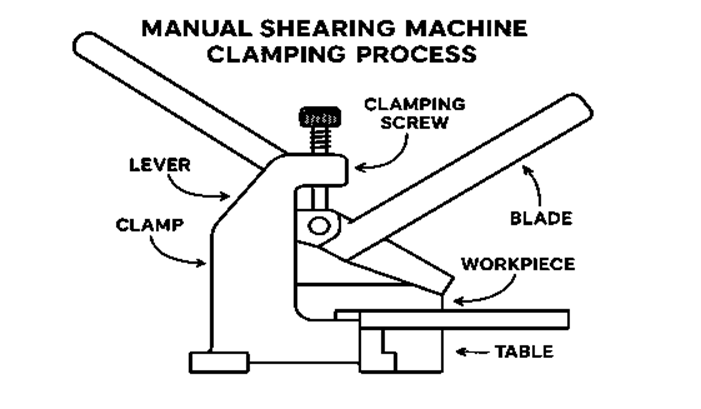

6. Worktable / Bed

· Flat surface where the workpiece is placed for cutting.

· May include guides or stops for accurate positioning.

7. Blade Guard (optional in some designs)

· Provides safety by covering the blades when not in use.

8. Hold-down Clamps (sometimes included)

· Hold the workpiece securely to prevent movement during cutting.

Process Steps

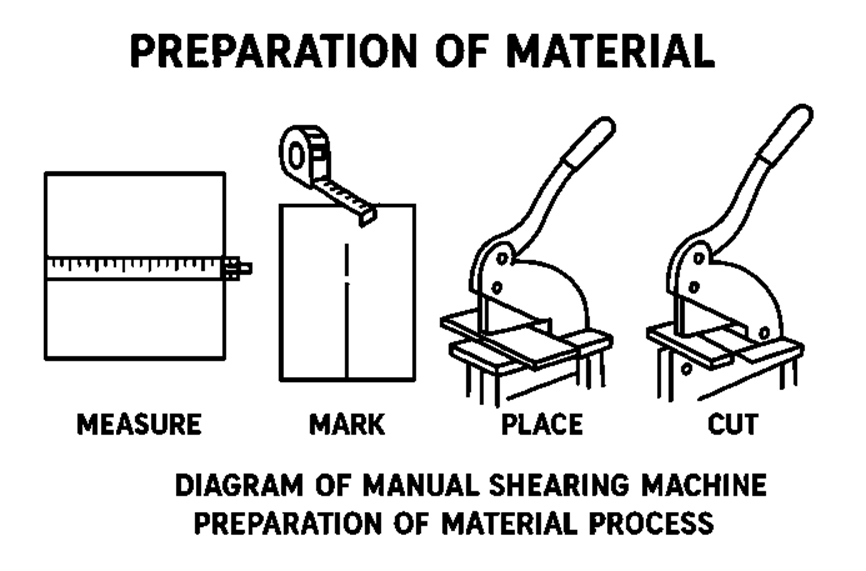

1. Preparation of Material

· Place the metal sheet (or workpiece) on the worktable.

· Adjust position using guides or markings for accurate cutting.

Secure the workpiece using hold-down clamps to prevent shifting.

2. Aligning the Blade

· Position the part of the sheet where the cut is desired directly under the upper blade.

3. Applying Force

· Pull the handle or lever downward.

· The lever multiplies the applied force and moves the upper blade downward

4. Shearing Action

· The upper blade moves down and presses the sheet against the lower blade.

· The material is sheared through the scissor-like action.

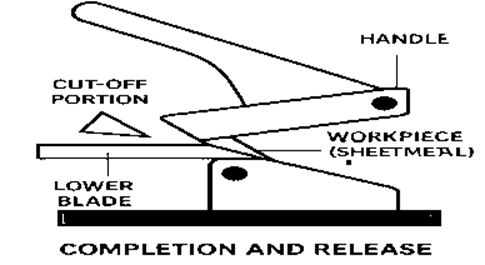

5. Completion and Release

· After the cut, release the handle.

· Remove the cut piece and prepare for the next operation. Fixed in position.

· Works together with the upper blade to create a scissor-like cutting action.

Capacity

The capacity of a manual shearing machine depends on the machine's size and construction but typically includes:

· Sheet Thickness: Up to 2–6 mm mild steel (depending on the model)

· Sheet Width: Typically 500 mm to 2000 mm

· Material: Mild steel, aluminum, copper sheets, plastic sheets (non-ferrous materials)

Note: Exact capacity depends on blade quality, leverage, and operator strength.

Applications

Manual shearing machines are used in small-scale and medium industries for cutting sheet metal. Common applications include:

· Sheet metal fabrication

· Cutting blanks for bending or forming

· HVAC ductwork fabrication

· Automotive body parts

· Roofing and cladding works

· Educational/training workshops

Advantages

1. Low Cost: Inexpensive to purchase and maintain.

2. No Power Required: Operates manually — ideal for areas without electricity.

3. Simple Operation: Easy to use with minimal training.

4. Low Maintenance: Fewer moving parts compared to motorized machines.

5. Portable: Can be moved easily in smaller workshops

Limitations

· Cannot cut hard materials like stainless steel or thick mild steel.

· Fixed blade gap: May not be adjustable for different materials or thicknesses.

· No automation: All cuts are manual and cannot be integrated into automated production lines.

· Operator skill-dependent: Quality and consistency depend on the operator’s experience.

· Safety Risk: Manual operation may pose safety risks if not handled properly.

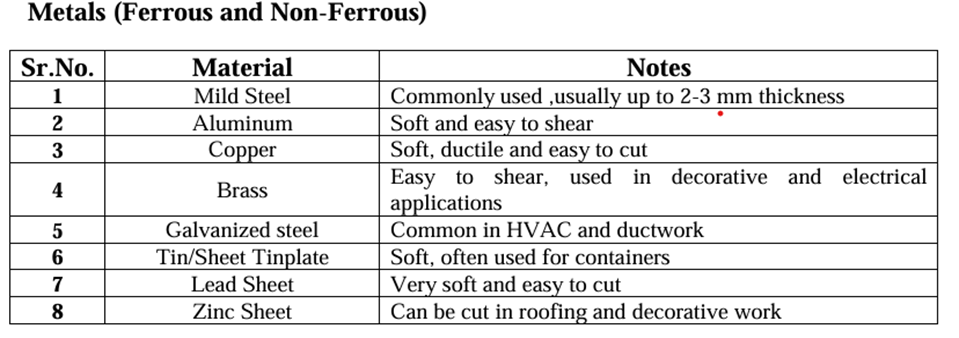

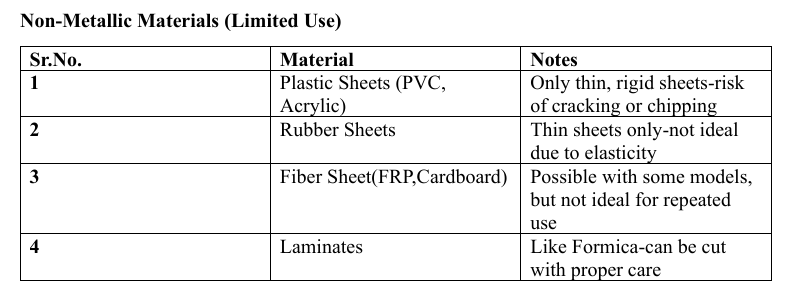

Materials That Can Be Cut Using a Manual Shearing Machine

Manual shearing machines are designed to cut sheet materials — mostly ductile, soft to medium hard metals, and some non-metals. Here's a list of common materials

Important Considerations

-Always check the material thickness, hardness, and machine specifications.

-Overloading or using inappropriate materials can damage blades or injure the operator.

-Use sharp, clean blades and maintain proper blade clearance for clean cuts.

-High-carbon steel, stainless steel, and hardened alloys are generally not suitable due to high hardness and wear on blades.