Manual Bending Machine

A manual bending machine is a mechanical device used to bend and shape sheet metal or other pliable materials into desired angles and forms. Unlike automated or CNC bending machines, a manual bending machine relies on human effort to operate, making it a cost-effective and straightforward solution for smaller workshops or jobs that don't require high-volume production.

Working Principle of a Manual Bending Machine

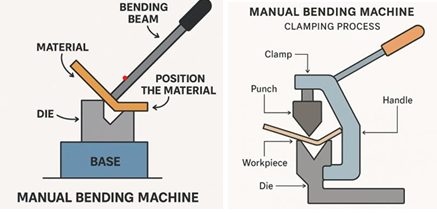

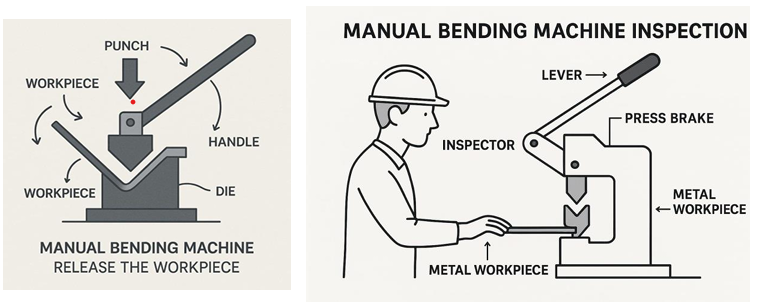

The working principle of a manual bending machine is based on mechanical leverage and manual force applied to a workpiece to create a bend at a desired angle and position. The process involves clamping, bending, and releasing the material.

Step-by-Step Working Principle:

1. Material Placement:

The metal sheet or workpiece is positioned on the machine’s flat surface or bending die. It is aligned according to the required bend line using marked guides or measurements. Before positioning the sheet, it is important to identify the dimensional as well as material limitations of the machine.

2. Clamping:

The material is clamped firmly in place using a clamping bar or finger (in the case of a box and pan brake) to prevent movement during bending.

3. Applying Force:

The material is clamped firmly in place using a clamping bar or finger (in the case of a box and pan brake) to prevent movement during bending. The operator pulls or pushes a lever or handle, which raises or lowers a bending leaf or beam. This movement forces the unclamped portion of the material to bend along the edge of the clamping surface or die.

4. Bending Action:

The bending leaf rotates the material around a fixed edge or radius to form the desired angle. The bend angle can be controlled manually by adjusting how far the lever is moved.

5. Releasing the Material:

Once the bend is completed, the lever is returned to its original position. The clamping mechanism is released, and the bent workpiece is removed.

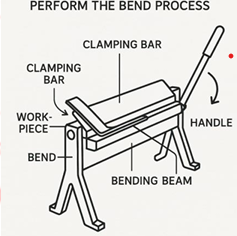

Key Elements Involved:

· Clamping Bar: Holds the workpiece steady.

· Bending Leaf/Beam: Applies the bending force.

· Angle Guides: Help the operator measure and control the bending angle.

· Levers/Handles: Used to apply manual force.

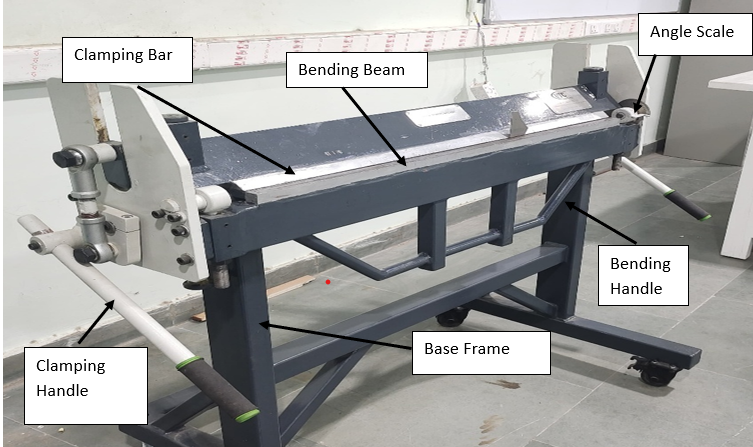

Components of a Manual Bending Machine

A manual bending machine consists of several key components that work together to perform the bending operation efficiently and accurately. Below is a list of the main parts and their functions:

1. Base Frame

Function: The main structure that supports all other components.

Material: Usually made from heavy-duty steel or cast iron for strength and stability.

2. Clamping Bar (Clamping Beam)

Function: Holds the workpiece firmly in place during bending.

Operation: Manually tightened or locked using clamps or levers.

3. Bending Leaf (Bending Beam)

Function: Moves upward or downward to bend the material against the clamping bar.

Operation: Activated manually via a lever or handle.

4. Bending Handle/Lever

Function: Provides mechanical leverage to operate the bending leaf.

Use: The operator pushes or pulls this handle to apply the bending force.

5. Hinge Mechanism

Function: Allows the bending leaf to pivot around a fixed axis for smooth and consistent bending.

Placement: Located at the junction of the frame and the bending beam.

6. Back Gauge/Stop

Function: Ensures consistent bend location and depth by positioning the workpiece.

Adjustment: Can be manually set for repeatable bends.

7. Angle Scale/Indicator

Function: Shows the current bending angle to assist in accuracy.

Location: Usually attached near the bending leaf.

8. Finger Dies (in Box and Pan Brakes)

Function: Adjustable blocks used to bend complex shapes, such as boxes or trays.

Customization: Can be rearranged or removed depending on the desired bend profile.

9. Support Arms or Workpiece Supports

Function: Help hold long or heavy metal sheets steady before and during bending.

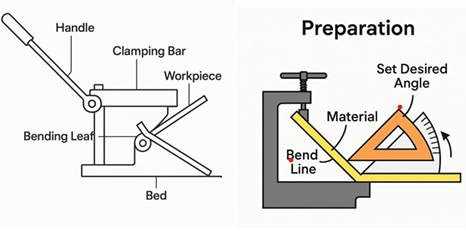

Process

1. Preparation

Select the Material: Choose the appropriate sheet metal (steel, aluminum, etc.) with suitable thickness. Mark the Bend Line: Use a marker or scribe to mark where the bend will occur.

2. Adjust the Back Gauge (if available):

Set it according to the bend line for consistency. Set the Desired Angle: Use the angle scale or a protractor if your machine has no built-in indicator.

3. Position the Material

Place the Sheet: Align the workpiece on the bending bed, with the bend line positioned at the edge of the clamping bar. Check Alignment: Ensure the material is straight and properly aligned for uniform bending.

Engage the Clamping Bar: Manually clamp the material in place using levers or knobs to prevent movement during bending.

4. Perform the Bend

Pull the Bending Handle/Lever: Slowly and steadily lift or lower the bending leaf to bend the exposed part of the sheet to the required angle. Check the Angle: Stop bending once the desired angle is achieved

5. Release the Workpiece Return the Handle:

Bring the bending beam back to its original position. Unclamp the Sheet: Release the clamping bar and remove the bent workpiece.

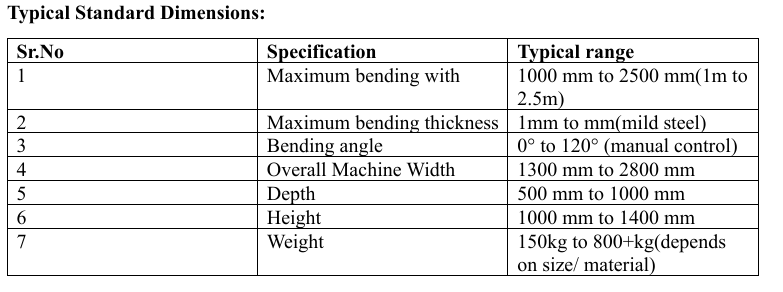

6. Inspection

Measure the Bend: Use an angle gauge or protractor to verify the bend. Repeat if Needed: Reposition and bend again if multiple bends are required for a single piece.

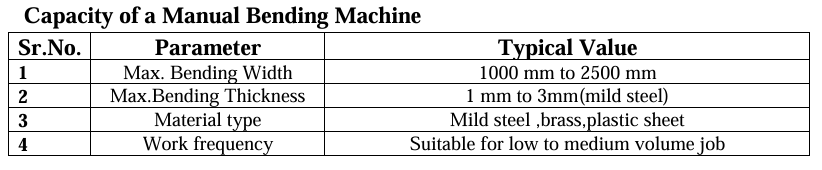

Standard Dimensions of a Manual Bending Machine

Manual bending machines come in various sizes depending on their application and capacity. However, there are general standard dimensions that are commonly found in workshop-grade machines.

Example Sizes by Type:

1. Small Workshop Brake (Bench Type)

Bending Width: ~1000 mm

Thickness Capacity: ~1.2 mm

Weight: ~150–200 kg

2. Medium Floor-Standing Brake

Bending Width: ~1250–2000 mm

Thickness Capacity: ~2 mm

Weight: ~300–500 kg

3. Heavy-Duty Manual Brake

Bending Width: ~2500 mm

Thickness Capacity: ~3 mm or more

Weight: ~600–1000+ kg

Applications

Manual bending machines are widely used in various sectors, especially where customization or small-batch fabrication is needed:

· Sheet metal workshops

· HVAC duct fabrication

· Electrical panel and box manufacturing

· Sign-making

· Automobile and repair shops

· Furniture and fixture making

· DIY projects and educational training

Advantages

· Low Cost: Affordable to purchase and operate.

· No Power Needed: Operates manually—ideal for remote or power-limited locations.

· Simple Design: Easy to learn and use.

· Portable: Some models can be moved and used on-site.

· Low Maintenance: Fewer parts, minimal wear.

· Custom Bends: Ideal for prototype and small batch production.

Disadvantages

· Limited Capacity: Not suitable for thick or very hard metals.

· Manual Labor: Requires physical effort and operator skill.

· Slower Output: Not ideal for mass production.

· Accuracy Limits: Depends heavily on operator precision.

· No Automation: Not suitable for complex or repetitive high-volume tasks.

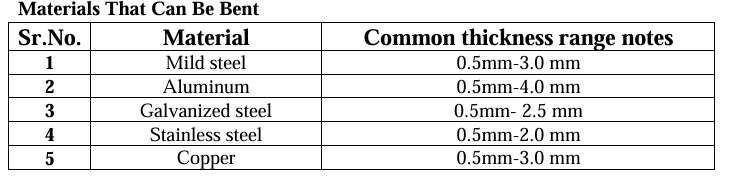

Materials That Can Be Bent Using a Manual Bending Machine

A manual bending machine is primarily designed for bending (not cutting) various types of sheet materials. However, it works best with materials that are ductile (i.e., can bend without cracking) and of moderate thickness.

Important Considerations

The thicker and harder the material, the more force is required. For hard metals like stainless steel, reduce the thickness to avoid damaging the machine. Always check the machine's rated capacity before bending any material.

Materials NOT Suitable for Manual Bending:

· Hardened or tool steels

· Cast iron (too brittle)

· Thick sheets beyond capacity (e.g., 5 mm steel)

· Very small or brittle plastic sheets (unless heated)

If you're referring to cutting materials (not bending), manual bending machines are not cutting machines—for cutting, you would use tools like:

· Shearing machines

· Guillotine cutters

· Plasma cutters (for thick/hard metals)

Safety Precautions

To operate a manual bending machine safely, follow these precautions:

1. Wear PPE: Safety glasses, gloves, and steel-toe shoes.

2. Check Machine Stability: Ensure it’s on a level, secure surface.

3. Avoid Loose Clothing/Jewelry: Prevent entanglement during operation.

4. Use Proper Lifting Techniques: When handling heavy sheets.

5. Keep Hands Clear: Stay clear of clamping and bending zones.

6. Inspect Equipment Regularly: Look for worn parts, cracks, or loose fittings.

7. Use Locking Mechanisms Properly: Ensure the workpiece is securely clamped