Lathe Machine

Basic Introduction

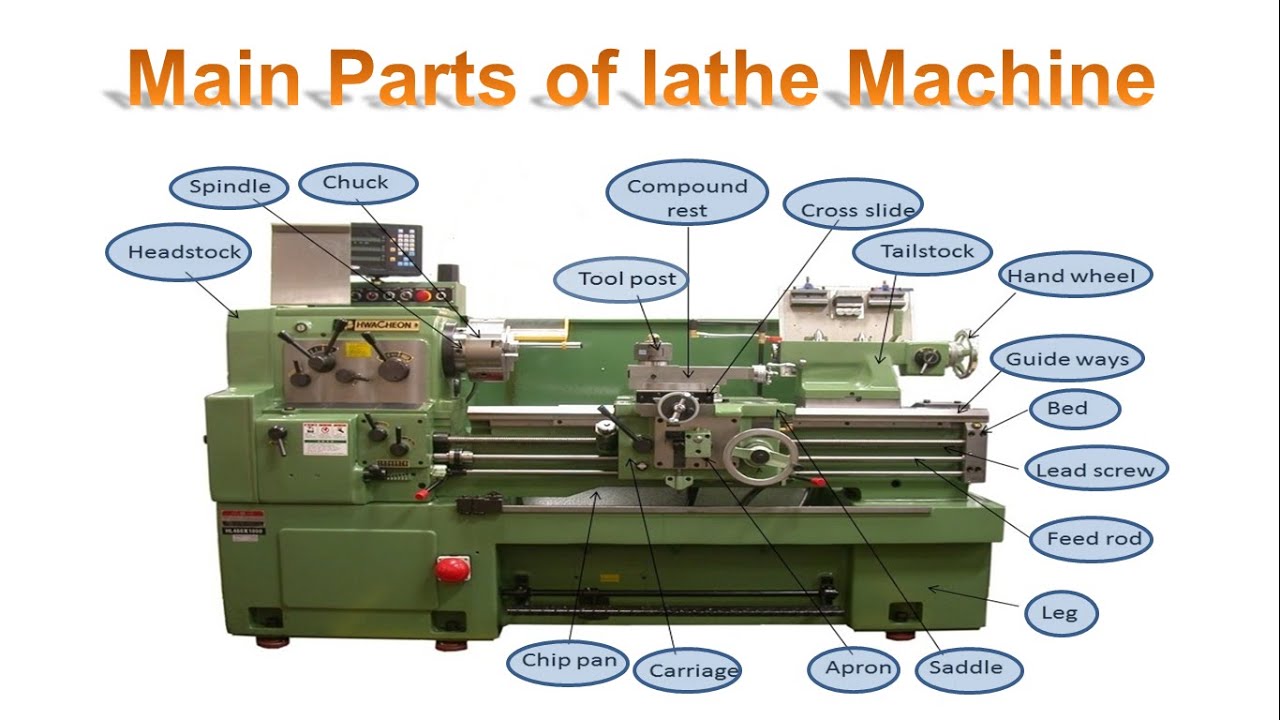

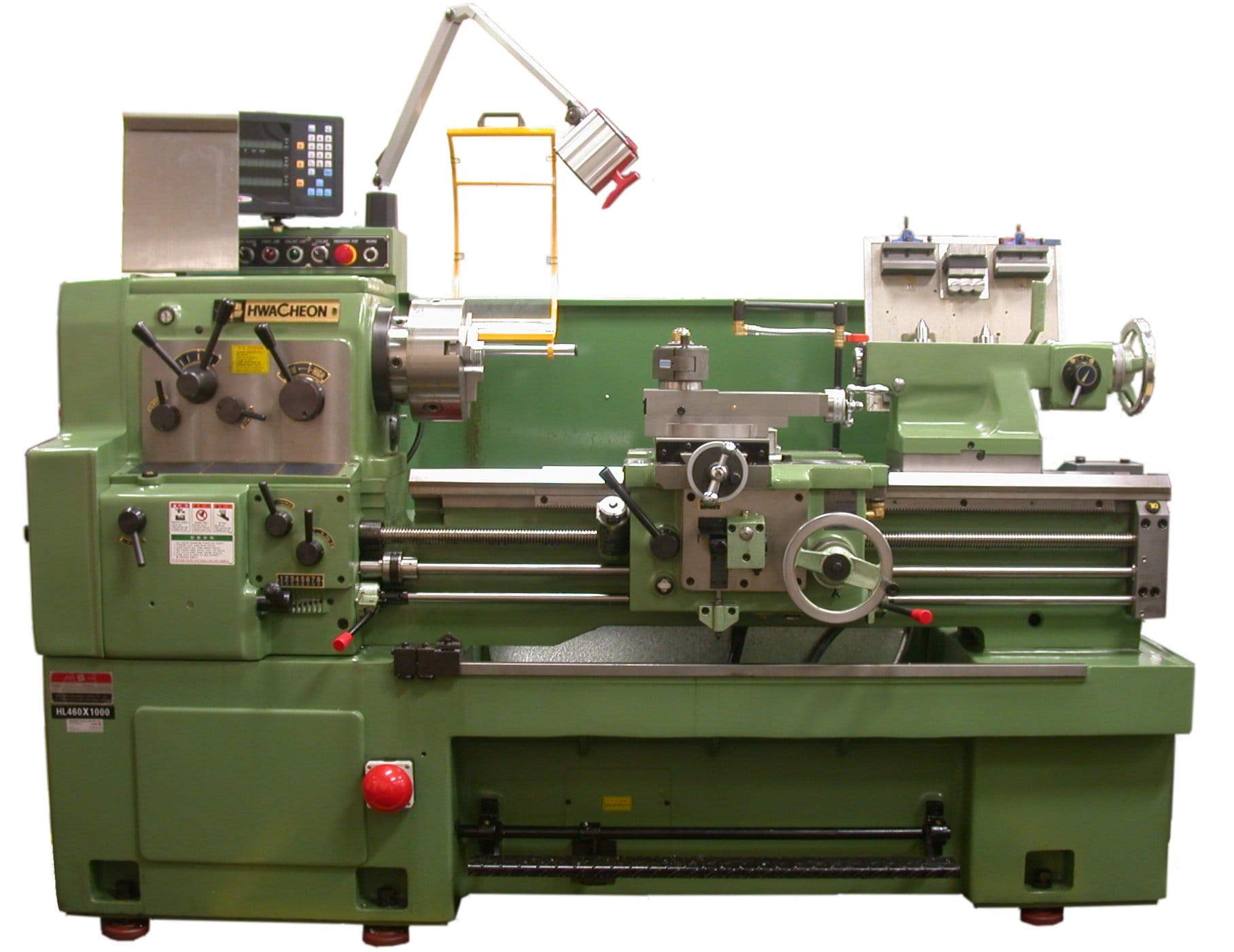

A centre lathe machine is a versatile machine tool used widely in workshops and industries. Its principal function is to rotate a workpiece about its axis, allowing for a stationary cutting tool to remove excess material and shape the component. The workpiece is held securely either in a chuck or between two centres, giving the machine its name. The lathe can process metals, plastics, and wood into cylindrical, conical, or complex shapes.

Key Features

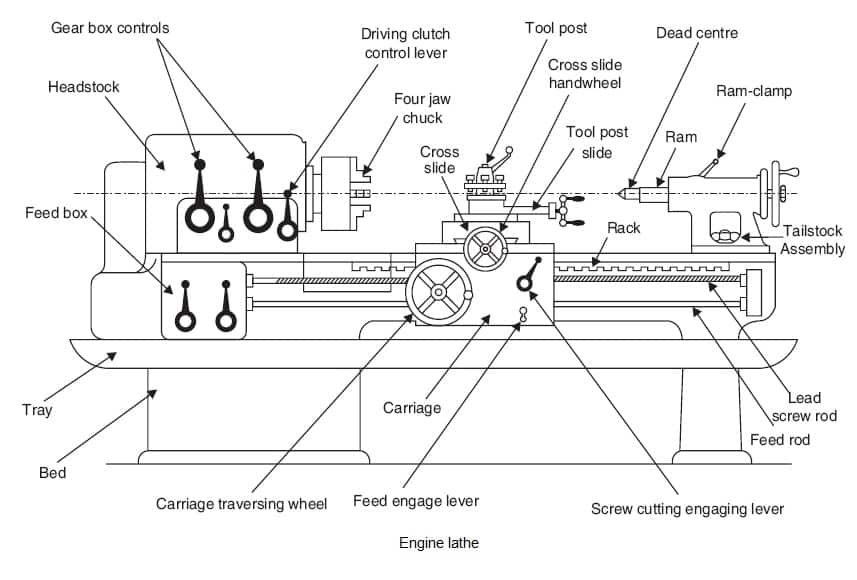

- Bed: Serves as the base, supporting all main components.

- Headstock: Mounted on the bed's left side; holds the main spindle, gears, and chucks.

- Tailstock: Positioned on the right, supporting the workpiece with a dead or live center.

- Carriage: Moves the cutting tool along the bed, supports tool post, cross slide, and apron.

- Lead Screw & Feed Mechanism: Enable precise movement for cutting and threading.

Here is a detailed explanation of centre lathe machine operations including the process steps for each operation:

Turning

Turning is the primary operation on a lathe, involving the removal of metal from the external diameter of a rotating workpiece to produce a cylindrical shape.

Process:

- Mount the workpiece in a chuck or between centers.

- Position the single-point cutting tool perpendicular to the workpiece surface.

- Set the lathe speed and feed rate according to material and finish required.

- Start the machine; the workpiece rotates, and the tool moves longitudinally along the axis, removing material.

- Measure and adjust the depth of cut to reach the desired diameter in rough and finish passes.

Details:

- Rough turning removes the bulk of the material quickly.

- Finish turning improves surface finish and dimensional accuracy.

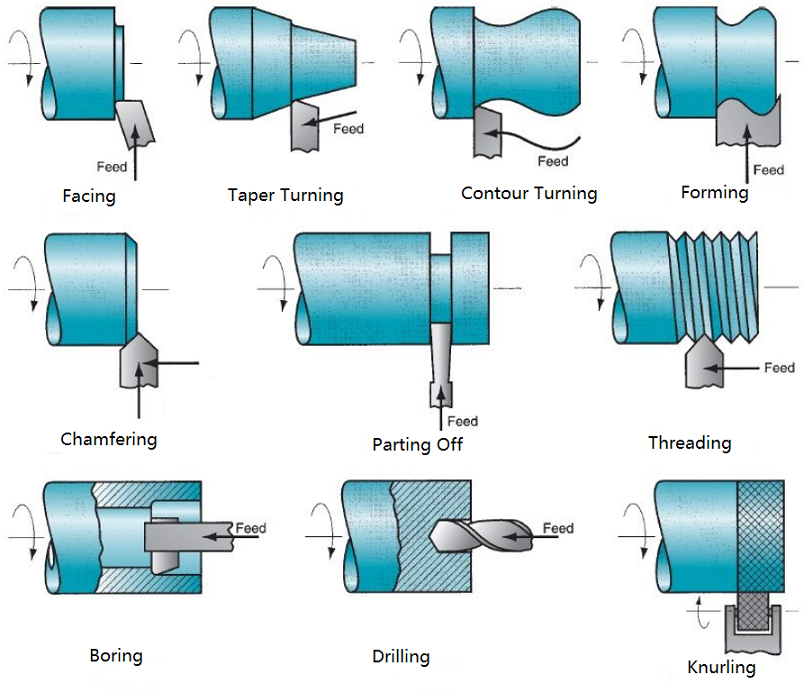

Facing

Facing creates a smooth, flat surface at the end of the workpiece.

Process:

- Set the cutting tool at the face of the rotating workpiece.

- The tool is fed radially inward from the edge towards the center.

- The operation produces a flat end face, often perpendicular to the axis.

Parting

Parting separates a finished workpiece or a section of it from the leftover material.

Process:

- Use a narrow cutting tool held perpendicular to the rotating workpiece.

- Feed the tool gradually into the workpiece until a complete cut-off is achieved.

Thread Cutting

Thread cutting produces helical grooves (internal/external threads) on the workpiece.

Process:

- Set the lathe’s lead screw to match the thread pitch.

- Use a pointed tool shaped to thread profile.

- Feed the tool longitudinally as the workpiece rotates, synchronized with lead screw rotation.

- Multiple passes gradually cut the full thread form.

Drilling

Drilling creates a hole along the axis of the rotating workpiece.

Process:

- Mount a drill bit in the tailstock chuck.

- Bring the rotating drill into the stationary workpiece by turning the tailstock handwheel.

- Drill to the desired depth.

Boring

Boring enlarges or finishes a pre-drilled hole.

Process:

- Mount a boring bar in the tool post.

- Feed the bar into the hole as the workpiece rotates.

- Remove material to achieve precise hole diameter and finish.

Knurling

Knurling forms a patterned surface on the workpiece for grip.

Process:

- Hold knurling tool against the rotating workpiece.

- Apply pressure, causing the pattern to imprint without cutting.

Grooving

Grooving cuts narrow grooves on the cylindrical surface.

Process:

- Use a special narrow tool.

- Feed the tool radially into the rotating surface to the required depth.

Chamfering

Chamfering bevels sharp edges or ends of the workpiece.

Process:

- Position the cutting tool at the workpiece edge.

- Feed at an angle to produce a beveled surface.