Laser Cutting - Acrylic

Booking Time: 2 Hrs

Max CMF Points Earned: 200 Pts.

Facility to Book: Laser Cutting - Acrylic

Description: This CO₂ laser cutting and engraving machine is designed for the precise and efficient processing of non-metallic materials like acrylic, wood, leather, and MDF. It features a powerful 100 W laser, a spacious 900 × 600 mm working area, and a high positioning accuracy of 0.01 mm, making it ideal for detailed cutting and engraving applications. Here are some examples of items that have been cut using this machine.

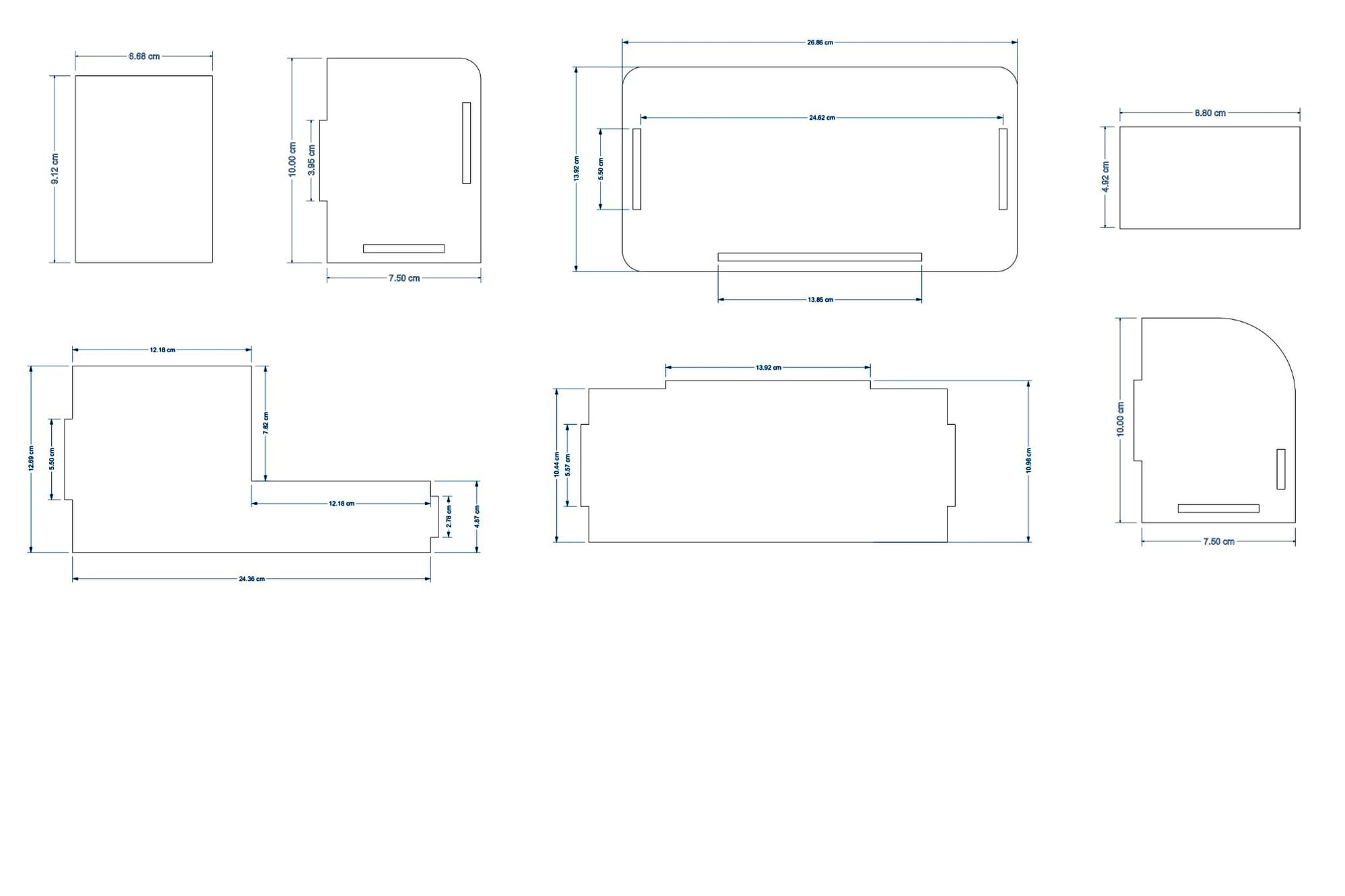

Part Name—Desk organiser

Material- Acrylic

Size: 270 mm X 140mm X 100mm

Step 1- Design Part in Inventor

- Use Inventor software to create the layout of the part.

- Export the design as a .dxf file.

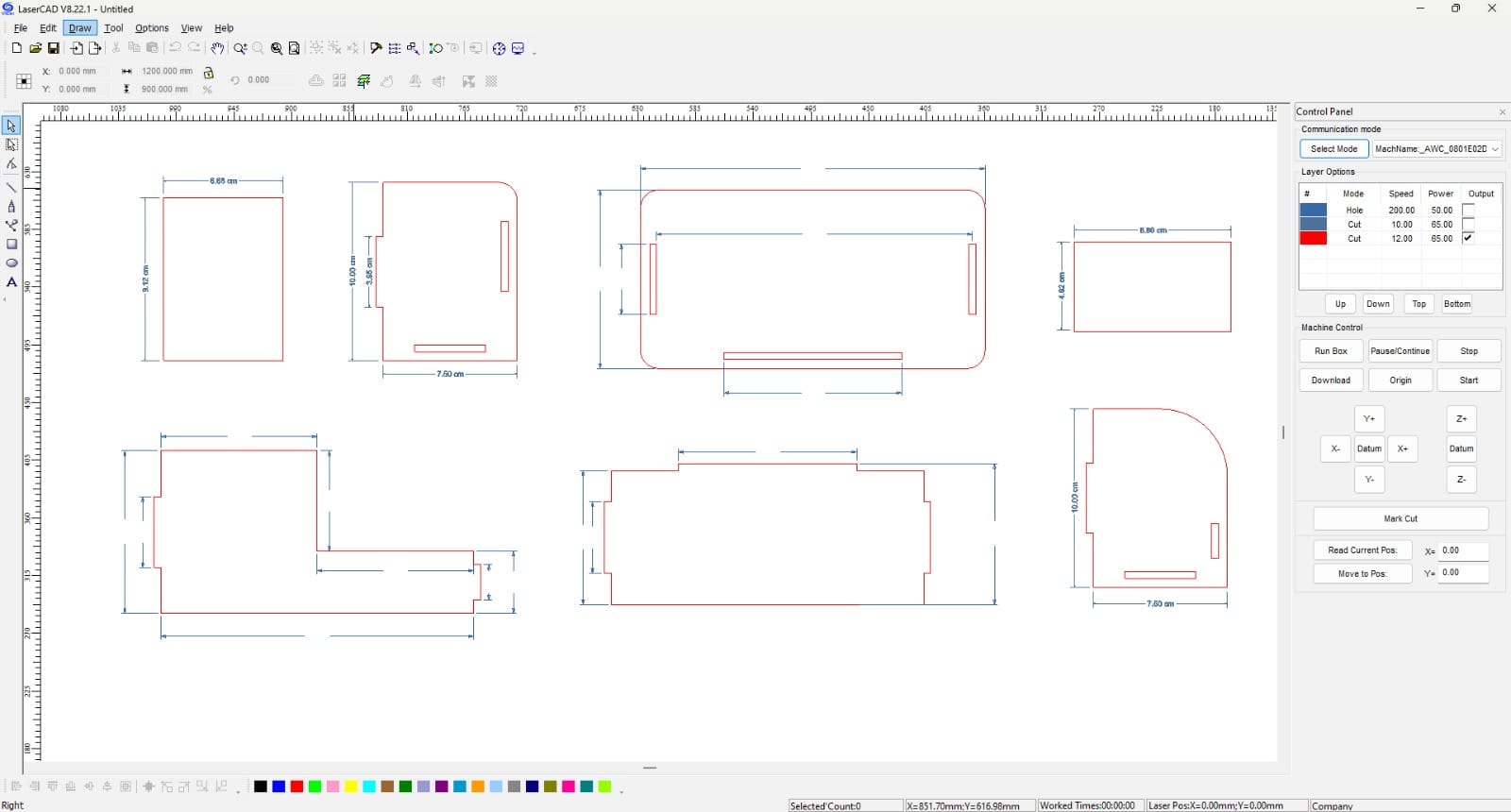

Step 2: Import into LaserCAD

- Open the .dxf file in LaserCAD software.

- Select all parts (highlight them in red).

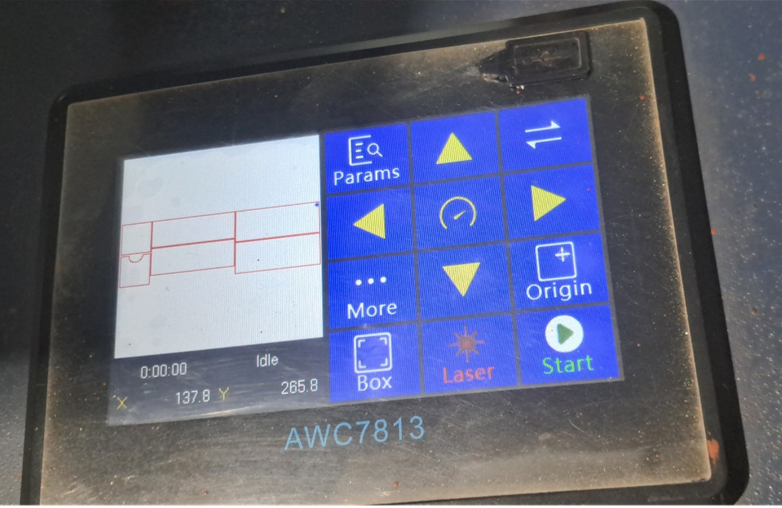

- Choose the AWC printer for compatibility.

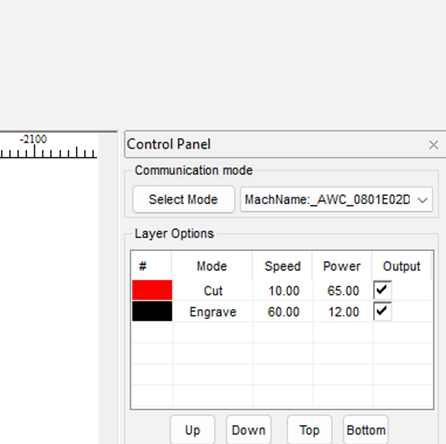

Step 3: Setup for Cutting

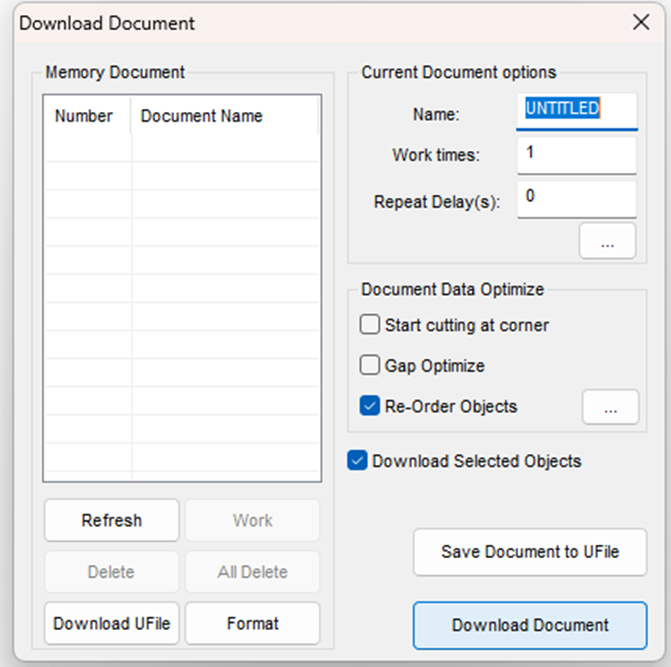

- Go to Machine Control ―>Click Download―> click Download Document

- Confirm material settings

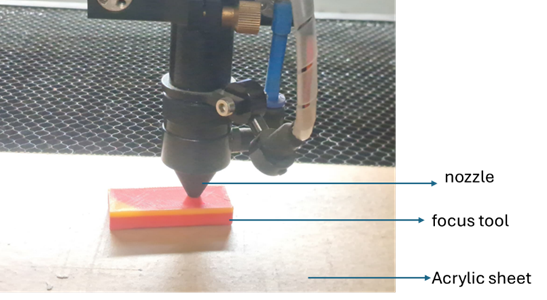

- Place the acrylic sheet on the bed and measure the distance between the nozzle and the sheet, which should be 8.2 mm, measured by the focus tool.

- Set the origin in the LaserCAD interface.

- Run the BOX function to perform a boundary scan.

Step 4: Perform Laser Cutting

- Load the material and start cutting with the CO₂ Laser Cutting Machine.

- Ensure safety measures are followed.

Final Product