Investment Casting

STEP 1: Make 3D Printed Replica for Metal Product (What you want to make)

STEP 2: Putting 3D printed part Covered by Silicon Rubber in Silicon-Rubber Vulcanizer. First Press by putting Silicon Rubber containing 3D Printed Object in Vulcanizer Manual Pressing.

Time: 1.5-2 Hrs, Temp.: 150 °C

Silicon Mold Final After Removing 3D Printed Part from Inside:

STEP 3 : Now Wax is heated and melted at 95 °C in Wax Injector and then at stable temp of 77 C .It is injected Silicon Rubber Mold at Nozzle temp 74° C.

Vacuum Time: 3 seconds

Injection Time: Depends on Cavity size. (For Our CMF Machine approx. time is 7-10 seconds.)

After injection WAX Replica of 3D Printed Part by Silicon Mold.

15-20 minutes to solidify wax in Mould.

After that Wax Replica is taken out of mould.

STEP: 4 Make Slurry with Gypsum Powder & Water in ratio 2.5:1.

STEP: 5 Vacuumize slurry and remove unnecessary gases (Time 2.5-3 Minutes )

STEP: 6 Fix Rubber in the bottom of the Steel Shell Base & Holes are cello-tapped.Place the Wax Replica at the bottom center of the Shell.Now Pour slurry in steel shell carefully & fill it completely.

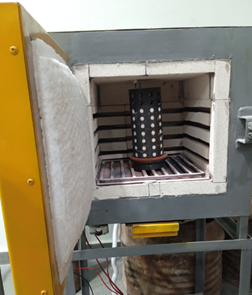

STEP :7 Vaccumize it again and Put it In Burnout furnace.

Set temp at 250 °C for Dewaxing ,Raise temp. to 750 °C for Gypsum mould hardening and maintain that temp. for 1 hour.

STEP:8 Parallelly Melt the desired quantity of target metal for ex. Brass (870°C) ,for poring raise temp additional to 100 °C for low viscosity.

Mold is kept in vibrator while efficient pouring in gypsum mould.

STEP:9 Now solidify it for half an hour. Then take the mould carefully and put it in water filled backet.Now gypsum will disolve in water and casted metal final product will be seprated from mould.

STEP :10 Keep the metal product in High Pressure Water Jet & Clean it using wearing built in gloves.

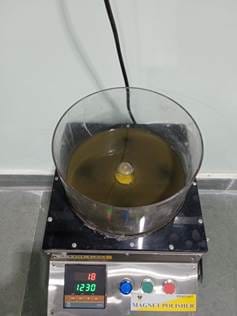

STEP 11 : For more fine cleaning now put the product in Magnetic Polisher.Fill the polisher to 1/3 size of the container, Mix 2 Spoons of Megnatic Liquid and also add 3 packets of Megnatic Needles according to your requirement.Now spin the mixure for 1200 seconds,It will run 600 seconds for clockwise and remaining 600 ACW.

Now the product is complete. This Process takes approxmately 8 Hours & a lot of safety measures.