FIBER LASER WELDING

Introduction Fiber Laser Welding

A fiber laser welding machine is a high-precision, advanced welding system that uses a fiber laser beam as the heat source to join metal parts. Unlike traditional welding methods that rely on electric arcs or gas flames, fiber laser welding employs a concentrated, high-energy laser beam transmitted through optical fiber. This allows for deep penetration, high-speed, and low-distortion welding, especially ideal for thin and reflective metals.

Figure 1: Fiber Laser Welding Machine

Key Features:

Laser Source: Fiber laser (Ytterbium-doped fiber)

Wavelength: ~1060–1080 nm

High Beam Quality: Enables precise and fine welding

Cooling System: Water or air-cooled

Control System: CNC or PLC controlled for automation

Laser Power Range: 500W to 6000W (commonly used in industry)

Working Principle

The fiber laser generates a high-energy laser beam.

The beam is transmitted through a fiber optic cable to the welding head.

The focused laser beam melts the base materials at the joint.

As the material cools, it forms a strong metallurgical bond.

Shielding gas (like Argon or Nitrogen) is used to protect the weld area from oxidation.

Fiber laser welding machines are high-precision tools widely used in industries for joining metal parts. These machines use a fiber laser beam as the heat source for welding. Here are the main components of a fiber laser welding machine.

1. Fiber Laser Source

The heart of the machine.

Generates a high-powered laser beam.

Made from rare-earth elements like ytterbium.

Types: Continuous Wave (CW) or Pulsed.

2. Fiber Laser Source

Transmits the laser beam from the source to the welding head.

Offers flexibility, low maintenance, and stable beam quality.

3. Welding Head (Laser Processing Head)

Directs and focuses the laser beam onto the workpiece.

Contains: Collimating lens (straightens the beam), Focusing lens (concentrates the beam), Protective lens (prevents contamination), and Nozzles (guide shielding gas).

4. CNC Control System / Controller

Manages the movement of the welding head or workpiece.

Controls parameters like laser power, speed, and path.

Supports automation and repeatable precision welding.

Human-Machine Interface (HMI) / Display Panel

Allows the operator to input commands and monitor welding conditions.

Touchscreen or software-based interface.

5. Shielding Gas Supply System

Provides inert gas (usually Argon or Nitrogen) to protect the weld pool from oxidation.

Flows through the welding head nozzle.

6. Cooling System (Chiller Unit)

Maintains optimal temperature of the laser source and optics.

Typically uses water to cool the components.

7. Power Supply

Powers all electronic and laser components.

Must be stable and sufficient for high-power operation.

8. Worktable / Welding Platform

A stable surface where the parts to be welded are placed.

May include fixtures, jigs, or a robotic arm for automation.

9. Optional: Robotic Arm or Motion System

For automated or complex welding paths.

Enhances speed, repeatability, and accuracy.

The process of fiber laser welding involves using a highly focused fiber laser beam to melt and fuse materials, typically metals, at the joint. It is known for precision, speed, and deep penetration with minimal distortion.

Step-by-Step Process of Fiber Laser Welding

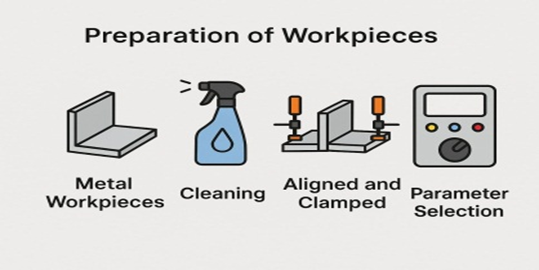

1. Preparation of Workpieces

Clean the metal surfaces to remove oil, rust, paint, or dirt.

Align and clamp the parts accurately to ensure a precise joint.

Select suitable parameters: laser power, welding speed, focus position, and shielding gas.

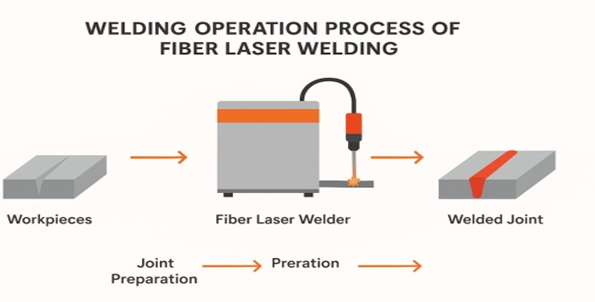

Figure 2: Preparation of Material

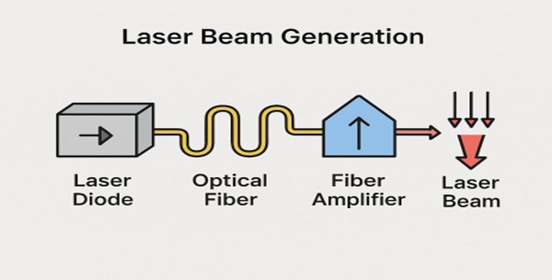

2. Laser Beam Generation

The fiber laser source generates a high-power laser beam (usually Ytterbium-doped fiber).

The beam is transmitted through a fiber optic cable with minimal loss.

Figure 3: Generation of Laser Beam

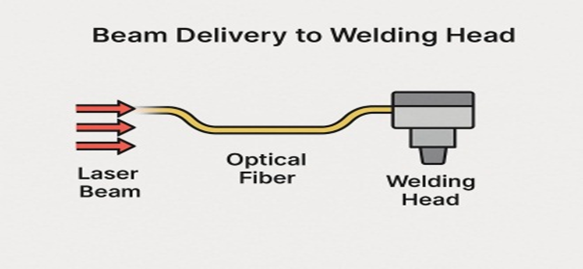

3. Beam Delivery to Welding Head

The laser beam reaches the welding head, where it is: Collimated (parallel rays),

Focused by a lens into a small spot for high energy density.

Figure 4: Laser Beam Delivery to Welding Head

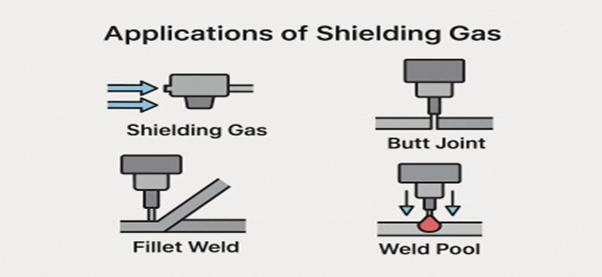

4. Application of Shielding Gas

Inert gas (Argon/Nitrogen) is delivered through the welding head nozzle.

This gas protects the molten metal from atmospheric contamination and oxidation.

Figure 5: Apply of Shielding Gas to Welding Joint

5. Welding Operation

The focused laser beam is applied to the joint area.

The intense heat melts the material and forms a weld pool.

Types of welding techniques: Keyhole welding (deep, narrow weld with high power density), Conduction welding (shallow welds with low power).

Figure 6: Welding operation

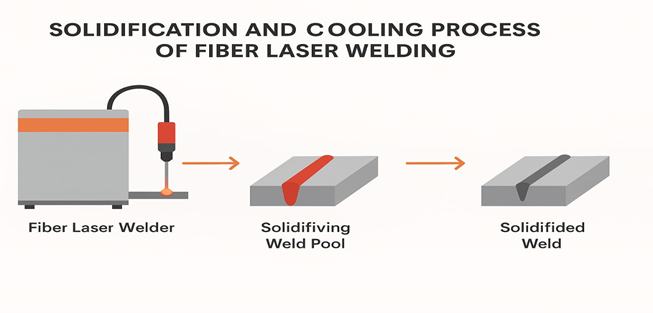

6. Solidification and Cooling

After the laser moves away, the molten pool solidifies rapidly, forming a strong joint.

The high cooling rate produces narrow heat-affected zones (HAZ) and minimizes distortion.

Figure 7: Solidification and Cooling of Welding Joint

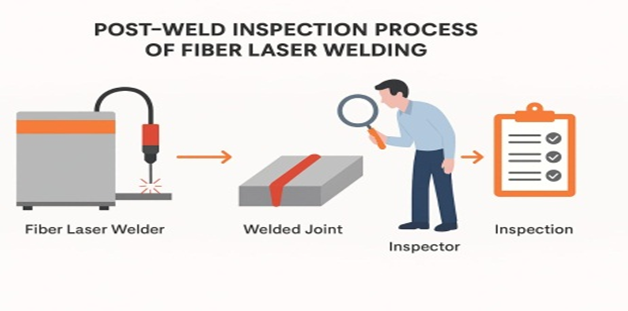

7. Post-Weld Inspection

Check weld quality visually or with tools like:X-ray inspection, ultrasonic testing, or dye penetrant testing.

Ensure there are no defects like cracks, porosity, or weak fusion.

Figure 8: Solidification and Cooling of Welding Joint

Capacity of Fiber Laser Welding Machine

|

Sr No. |

Parameter |

Typical Range / Value |

|

1 |

Laser

Power Output |

500

W – 6000 W (common); up to 12,000 W (industrial) |

|

2 |

Material

Thickness Welding Range |

0.2

mm – 10 mm (depends on power & material) |

|

3 |

Welding

Speed |

0.1

– 10 m/min (varies by thickness, power, and material) |

|

4 |

Duty

Cycle |

100%

(continuous operation) |

|

5 |

Supported

Materials |

Stainless

Steel, Mild Steel, Aluminum, Copper, Titanium, Brass |

|

6 |

Cooling

Requirement |

Water

cooling (chiller system) |

|

7 |

Shielding

Gas |

Argon,

Nitrogen, Helium (optional based on material) |

General Specifications

|

Sr. No. |

Specification |

Details |

|

1 |

Laser Type |

Continuous Wave (CW) or Pulsed Fiber

Laser |

|

2 |

Wavelength |

1064 nm (near-infrared) |

|

3 |

Beam Quality |

High (M² < 1.5) |

|

4 |

Focusing Lens |

Focal Length: 100 mm to 200 mm |

|

5 |

Welding Modes |

Conduction, Keyhole, Pulse |

|

6 |

Control System |

CNC / PLC / HMI / PC-based |

|

7 |

Cooling System |

Industrial water chiller |

|

8 |

Power Supply |

220V or 380V 3-phase (depending on

model) |

|

9 |

Weight & Size |

Varies: 300 kg – 1000+ kg; machine

footprint depends on table size and

configuration |

Programming Tips for Fiber Laser Welding

Always Pre-Test Settings: Material surface, clamping, and gas flow can affect results.

Wobble Welding: If welding gaps or thin parts, use wobble mode (1–3 mm @ 100–200 Hz).

Edge Preparation: For 2 mm+ thickness, ensure edge beveling or proper fit-up.

Focus Calibration: Auto-focus or manual setup must be precise; incorrect focus = poor weld.

Gas Delay Settings: Setup pre-gas and post-gas delays (e.g., 0.5–1s) to avoid oxidation.

Advantages of Fiber Laser Welding

High Precision: Enables fine, accurate welds—ideal for small or delicate components.

High Welding Speed: 2–10 times faster than traditional methods like TIG/MIG.

Deep Penetration: Can weld thick materials (up to 10 mm with higher power).

Low Heat Input: Less distortion and minimal heat-affected zone (HAZ).

Automation Compatible: Easily integrates with CNC systems or robotic arms.

Low Maintenance: No electrodes or consumables; fiber laser sources last long (~100,000 hrs).

Versatile Materials: Works on stainless steel, carbon steel, aluminum, brass, copper, etc.

Clean Process: Little spatter, no filler material required in many cases.

Disadvantages of Fiber Laser Welding

High Initial Cost: Expensive setup, especially for high-power machines.

Reflective Material Challenges: Copper, aluminum, brass reflect laser; require more power or special setup.

Joint Preparation Critical: Gaps and misalignments can reduce weld quality—tight tolerance required.

Limited Color Matching: For visible joints, weld color may not match (esp. on decorative parts).

Training Required: Operators must be trained in laser parameters, focus control, and safety.

Limited for Very Thick Sections (>10mm):May require multiple passes or hybrid processes.

Limitations of Fiber Laser Welding

Not ideal for thick: aluminum or copper (>3 mm) on 2kW machine May require 3kW+ or hybrid laser-MIG setup

Gap sensitivity:Needs precision fixturing; can't bridge gaps like arc welding

Not suitable for painted or dirty surface: Requires clean, oxide-free surfaces

High reflection risk: Reflective materials can damage optics or laser head

High Power Demand: Requires stable industrial 3-phase power supply

Applications:

Automobile industry: welding battery packs, gears, doors

Medical devices: stainless steel surgical tools

Electronics: precision welding of sensors, metal housings

Aerospace: high-strength, lightweight alloy welding

Jewellery and consumer goods: fine, detailed joining

Safety Precautions for Fiber Laser Welding

Wear Laser Safety Glasses (OD 6+): Protects eyes from invisible infrared laser radiation(1064 nm)

Operator Training: Only trained personnel should operate the machine.

Ventilation & Fume Extraction: Welding fumes can be hazardous—use proper filters or exhaust systems

Emergency Stop & Interlocks: Ensure machine has E-stop, interlock doors, and chiller monitoring

Check Cooling System: Laser must not operate without adequate water cooling

Avoid Reflective Surfaces Nearby: Reflected beam can cause unintended burns or equipment damage.