Electrode Fabrication for Metal-Air Battery

Are you passionate about clean energy and cutting-edge technology? Join our exciting research project, "Electrode Fabrication for Metal-Air Battery," to contribute to the future of sustainable energy! This project offers hands-on experience in developing electrodes for metal-air batteries, a promising technology for affordable and eco-friendly energy storage. Dive into the world of electrochemistry, materials science, and clean tech innovation while gaining valuable skills for your academic and professional journey.

Project Description

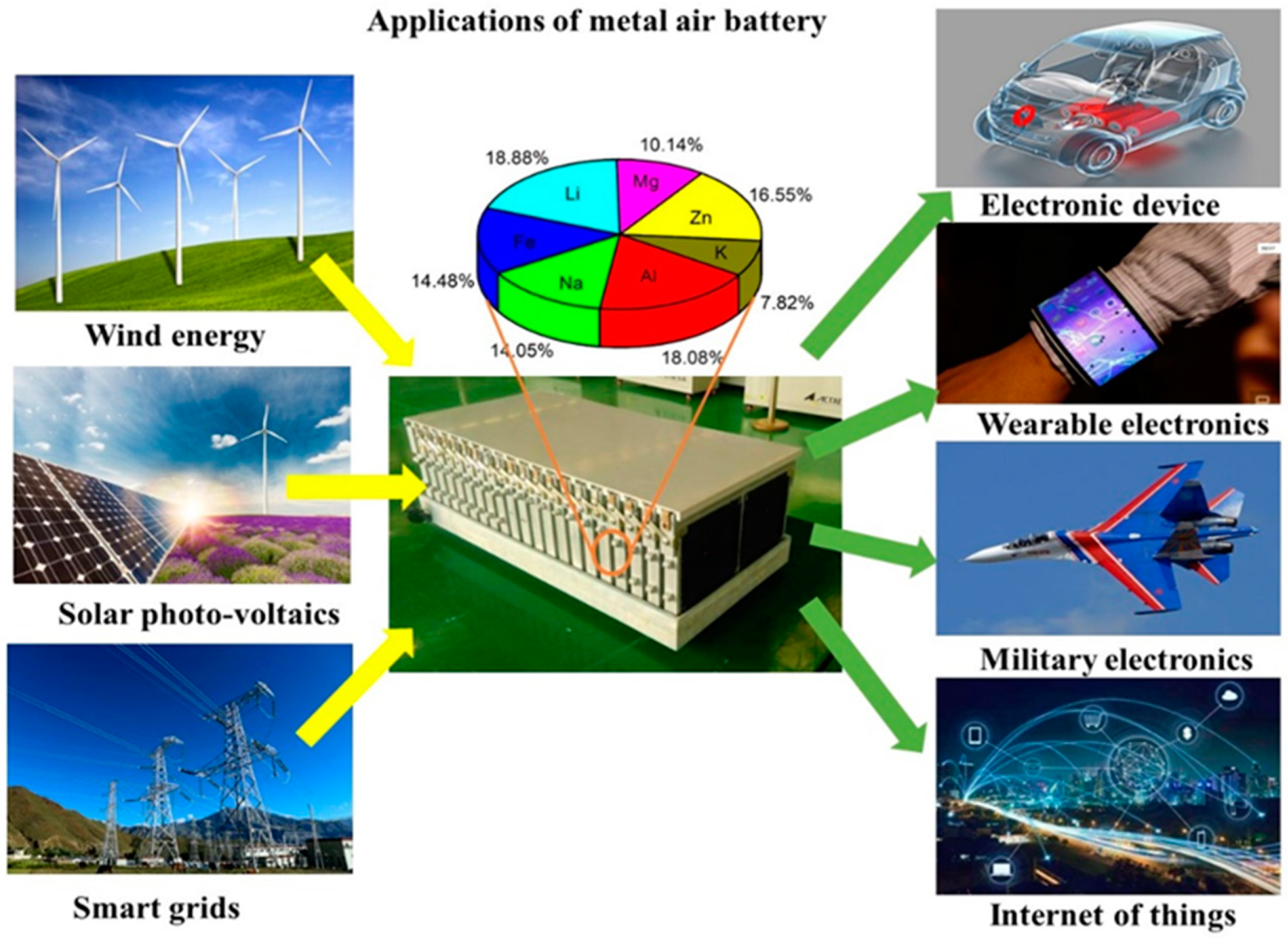

The Electrode Fabrication for Metal-Air Battery project focuses on designing, fabricating, and testing electrodes for metal-air batteries, a class of electrochemical systems that use metals (e.g., zinc, aluminum, or others) and oxygen from air to store energy.

A metal–air battery generates electricity through a redox reaction between a metal anode (like iron or aluminum) and oxygen from the air at the cathode. The metal undergoes oxidation, releasing electrons, while oxygen is reduced at the air cathode. This flow of electrons through an external circuit provides usable electrical energy. The electrolyte allows ion movement between electrodes, completing the circuit. The battery is lightweight, high in energy density, and ideal for clean energy applications.

Importance of the Project

This project offers a unique opportunity to contribute to the global shift toward clean energy. Metal-air batteries are a promising technology due to their:

- High Energy Density: Deliver more energy per unit weight than traditional batteries, ideal for portable and grid applications.

- Sustainability: Utilize abundant materials (e.g., zinc, aluminum, oxygen), reducing dependence on scarce resources like lithium.

- Cost-Effectiveness: Lower production costs compared to lithium-ion batteries, enabling affordable energy storage.

- Environmental Benefits: Eco-friendly chemistry and recyclability support circular economy goals.

Skill Required

1. 2D Drawing

2. CAD Design

3. Machining

4. Metal Casting

5. Heat Treatment

6. Dimensional Tolerance & Fit Understanding