Electric Motor Design

Brief Description about the problem

This project involves a complete fabricating a special type of motor. Once fabricated, we can test it in the lab.

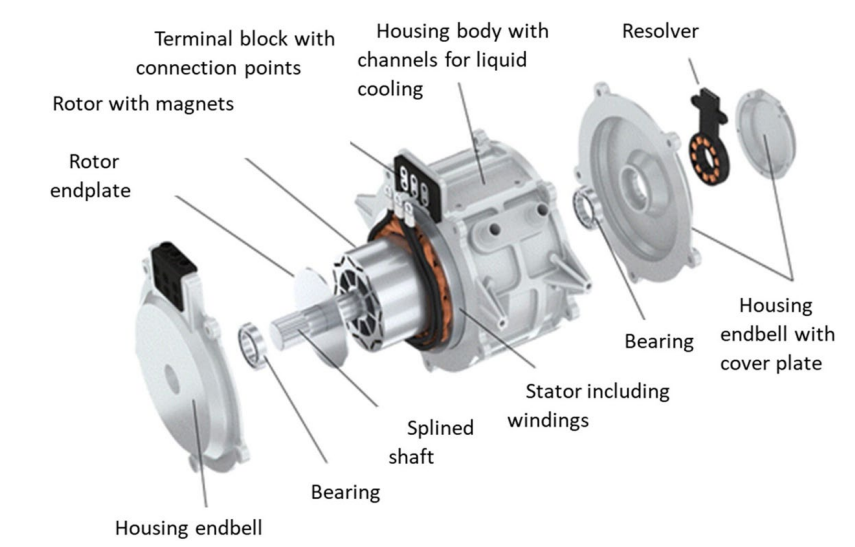

The complete operational motor has following parts that need to be fabricated:

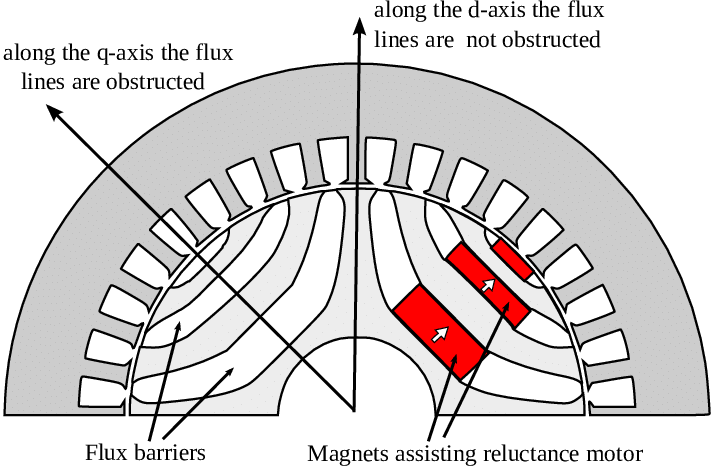

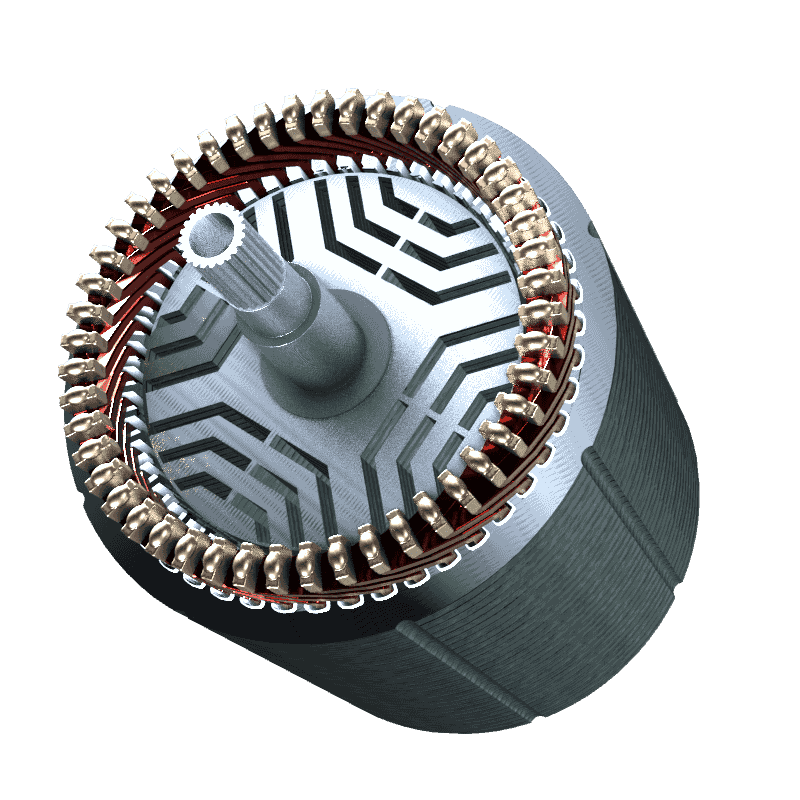

- Stator and Rotor Laminations. These are shapes cut out of the thin steel sheets and glued together using epoxy.

- Shaft and Bearings. This needs to be installed in the rotor center so that we can support the rotor using Bearings. Bearings can be purchased.

- Housing Endbell. Endbells have the bearings in the center to support the rotating shaft. The design of endbell should be naturally aligning with stator. This way when the rotor is inserted in the stator, the airgap must be maintained all around the periphery.

- Stator Winding. These are copper wire coils arranged in the stator slots. We will help you with this.

Major Challenge in the design is to maintain tight geometric tolerances. Since the stator, rotor, endbells, bearings and shaft has to be properly aligned, otherwise the spinning part may rub against the stationary part.

How the motor laminations are made using Laser cutting. We can perform the similar task using wire EDM as well.

Creating gear using Wire EMD, we can use the same method for the motor stator and rotor fabrication.

Skills Required

- Wire EMD cutting/ Metal Laser Cutting

- Lathe for machining shaft

- Milling or Mould Casting for fabricating Endbells

- CAD Design

- Programming Texas Instrument Microcontroller using Matlab (Optional)