20251ROB6: River Surface Waste Cleaning Machine

Brief Description and Functionality

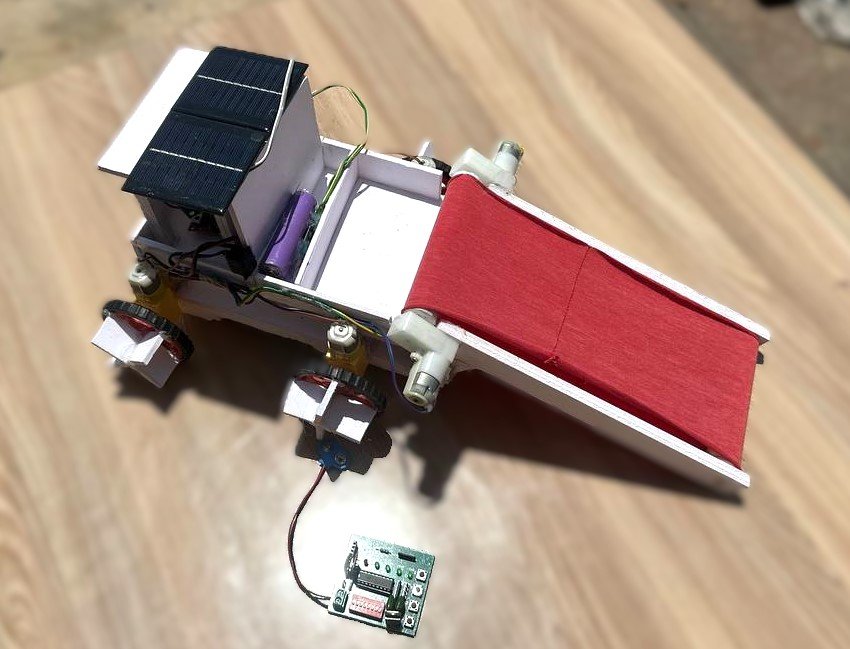

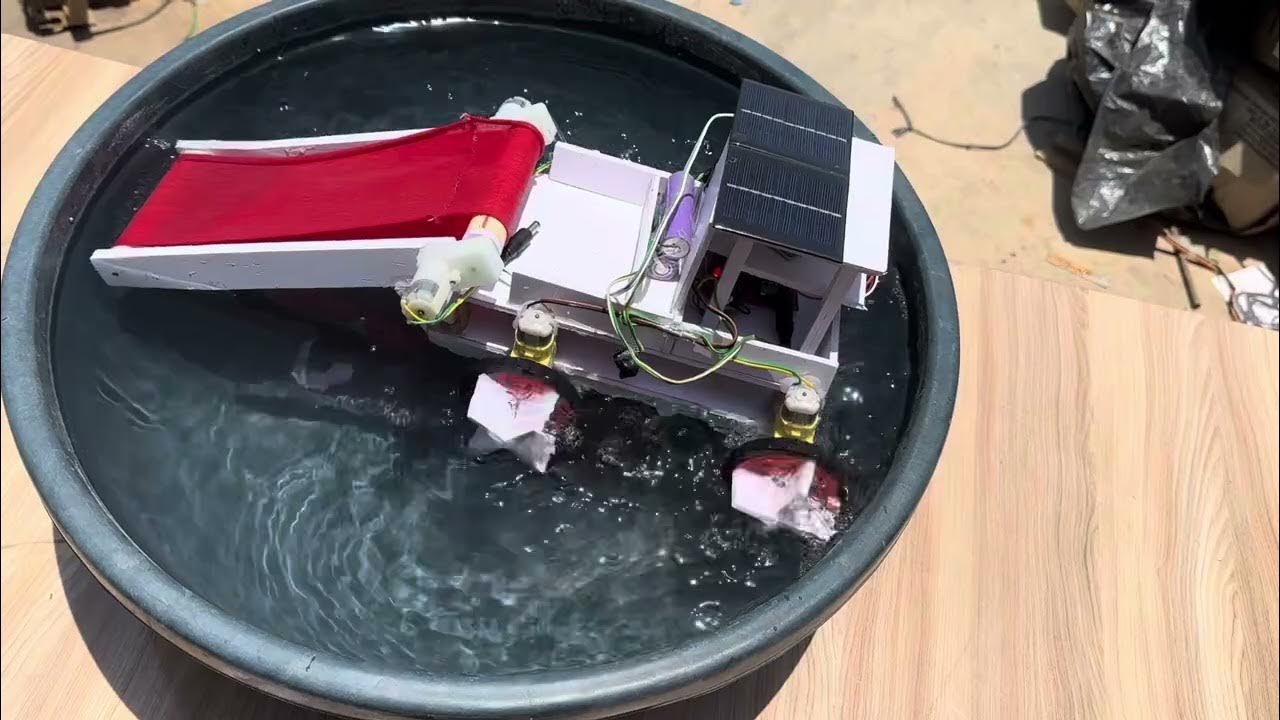

A river surface waste cleaning machine is an automated or semi-automated machine designed to remove floating waste such as plastic, leaves, and other debris from the surface of rivers, lakes, or canals. Typically equipped with a conveyor belt mechanism, the robot collects waste using rotating paddles or scoops that lift the debris onto a conveyor and deposit it into a collection bin.

Applications

- Water Pollution Control

- Environmental Conservation

- Support for Cleanup Initiatives

- Educational and Awareness Tool

- Data Collection and Monitoring

Working

The River Surface Waste Cleaning Machine is engineered to operate on the principle of mechanical collection and conveyor-based extraction, designed specifically for floating waste removal from water surfaces.

1. Buoyant Structure and Stability

- The machine is built on a catamaran-style or pontoon-based float to ensure stability.

- It provides a stable base for all mounted equipment like motors, conveyors, and bins.

2. Waste Capturing System

- Guiding arms/skimmers extend outward at the front.

- These direct floating debris toward the intake mouth of the machine.

- They work passively with water flow or dynamically if the machine is moving.

3. Conveyor Belt Mechanism

- At the intake zone, a rotating conveyor belt (with perforated or mesh paddles) scoops waste from the water surface.

- The belt is powered by an electric or solar motor, typically using a DC gear motor.

- The conveyor rotates upward and backward, lifting waste from the water.

4. Waste Elevation and Collection

- As the conveyor lifts, gravity and mechanical alignment allow waste to fall into a collection bin or hopper at the rear.

- Excess water drains through the perforations in the belt, minimizing liquid in the waste bin.

5. Propulsion System (if mobile)

- DC motors or paddle wheels propel the machine using battery or solar energy.

- Navigation is controlled manually or via a remote-control unit, allowing directional movement to cover wider areas.

6. Control System

- A basic electrical control circuit or a microcontroller regulates motor speeds, timing, and conveyor activation.

- Some systems integrate limit switches or ultrasonic sensors to detect bin full levels or waterline.

7. Power Supply

- Powered by rechargeable batteries, possibly connected to solar panels mounted on top.

- This enables off-grid, sustainable operation.

8. Waste Disposal Cycle

- When the bin is full, the machine is brought to shore.

- Waste is manually or mechanically removed.

- The machine is then re-deployed to continue operations.

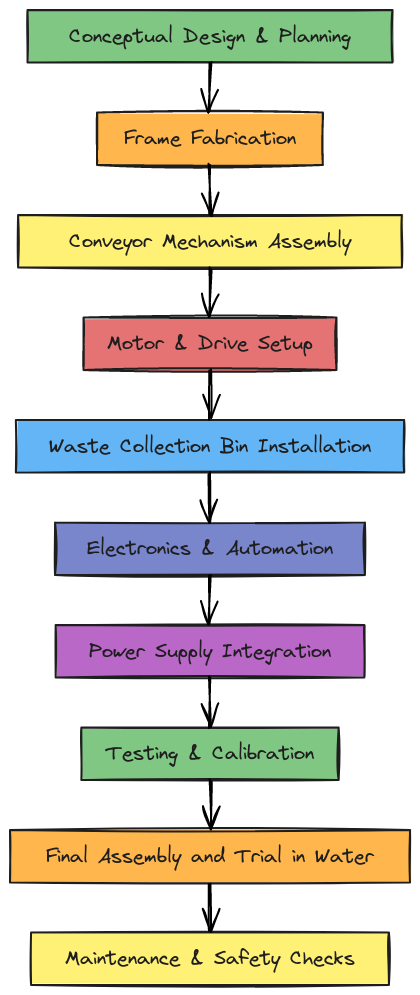

Flow chart of the fabrication steps

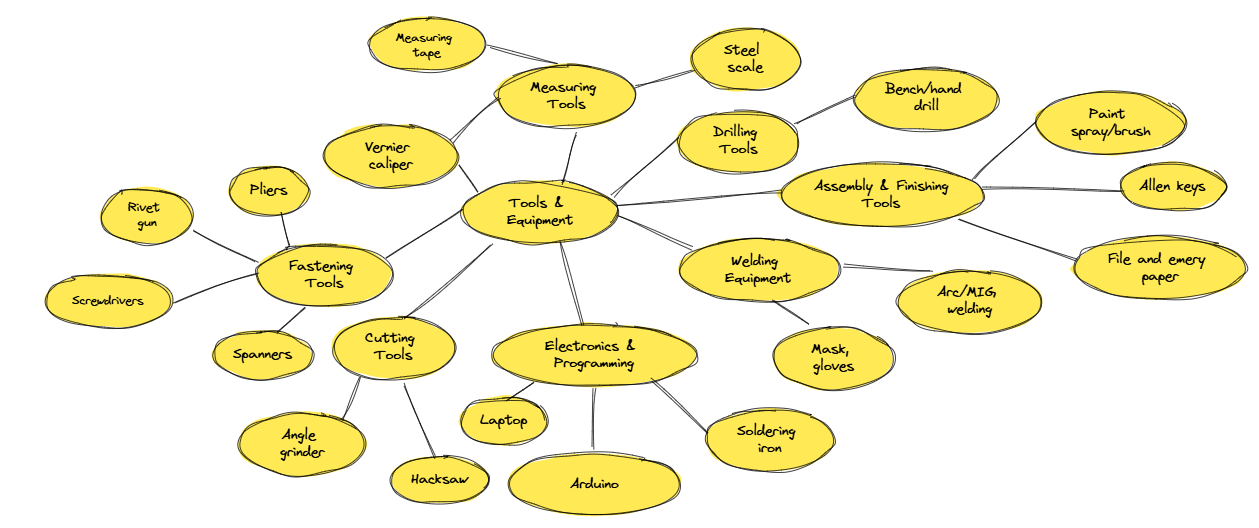

Tools and Equipments Required

Market Survey

River Cleaner Robot – SR Robotics

The River Cleaner Robot is an eco-friendly device designed to remove debris and waste materials from water bodies. It uses solar power, remote control, and a conveyer belt mechanism to efficiently collect and transport waste. No Branding. 100% working. Tested by S.R. Robotics. FREE Report + Ppt + Synopsis. FREE Shipping.

Useful Resources

River Cleaner Boat | best science Project | inspire Award Project

contact us for this project 9024388937We Provide Complete Hardware Project (Totally Handmade Easy To Submit In College And School ) with project report +ppt…

WasteShark demonstration @ranmarine

👉 LEARN MORE:https://ranmarine.io👉 ABOUT US:RanMarine Technology specializes in the design and development of industrial autonomous surface vessels (AS…

Razer helped design a trash collecting robot to clean up plastic pollution

Gaming giant Razer has partnered with a small company called Clearbot to help design an autonomous trash-collecting boat that can identify floating garbage i…

Skills Required

- CAD Design

- 3D Printing FDM

- Manual Soldering

- Arduino Programming

- Machining on Lathe

- Milling

- Drilling

- Sheet metal and Sheet metal bending

- Acrylic sheet cutting

- Threading

- Welding