20251ROB5: Portable road sign maker

Brief Description & Functionality

A Portable Road Sign Maker is a compact, mobile system designed to quickly create, customise, and deploy temporary road signs on the go. It is ideal for use in construction zones, traffic management, emergency routing, and event-based crowd control.

- Reduces reliance on pre-manufactured signage

- Saves time during urgent deployments

- Enables custom designs or temporary alerts

- Suitable for remote areas or on-site roadwork

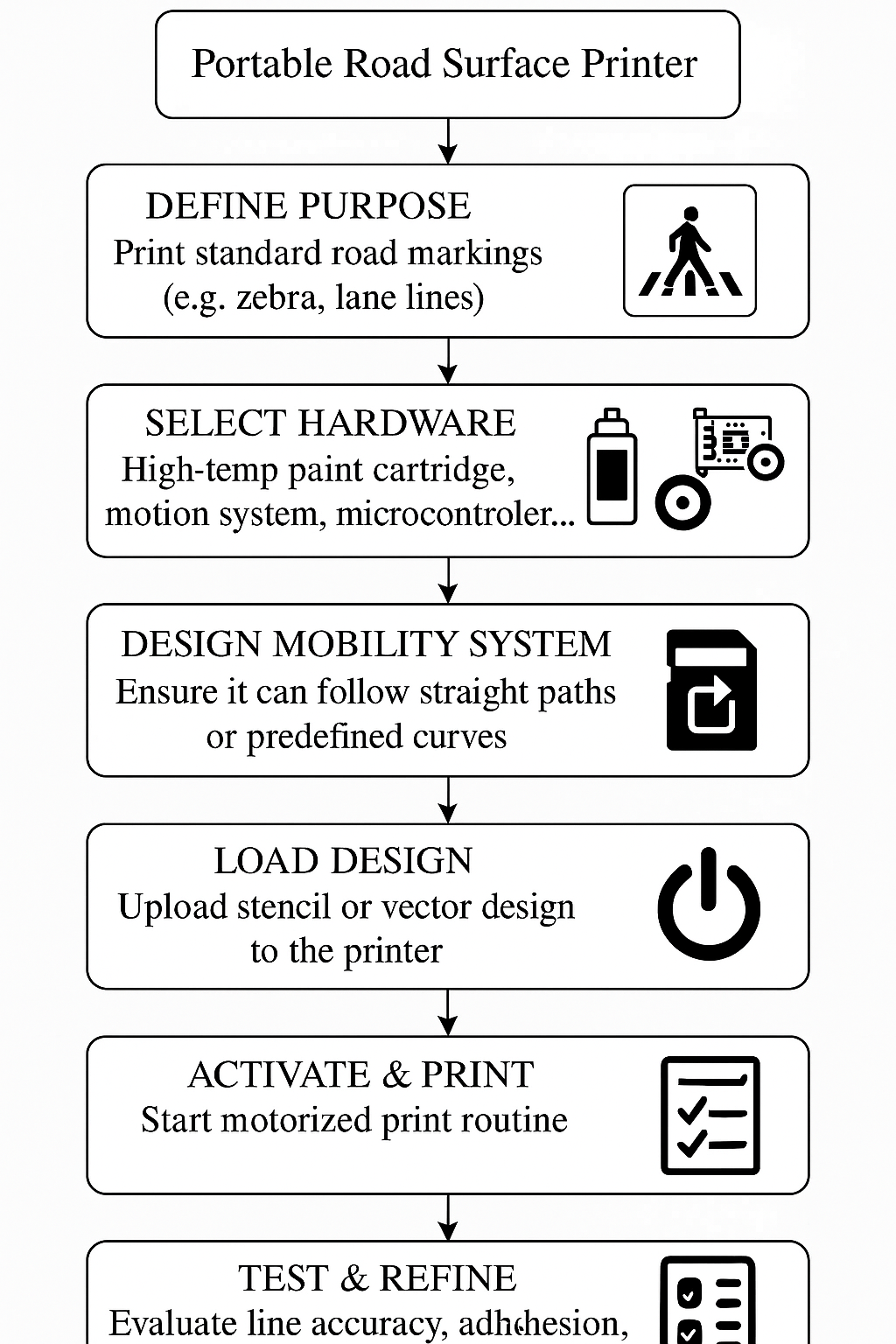

Working Principle:

This system combines sign-design software, a material feeding system, and a cutting or printing mechanism to produce signs quickly. Depending on the design, it can be manual, semi-automatic, or fully electronic.

Direct Printing System – Uses UV or solvent-based printers to print road signs directly on metal, plastic, or reflective sheets

These are operated via a laptop interface, touchscreen, or preloaded templates.

How Equipment Works:

| Component | Description |

|---|---|

| Cutting/Printing Head | Vinyl blade (like Cricut/Silhouette) or large-format printer |

| Media Feeding System | Rollers for reflective tape, sticker sheets, metal boards |

| Controller/Interface | Touchscreen or PC-connected software |

| Design Software | CorelDRAW, Adobe Illustrator, custom sign template editor |

| Power Supply | Battery pack or vehicle-based inverter |

| Frame & Mobility | Wheeled structure for portability |

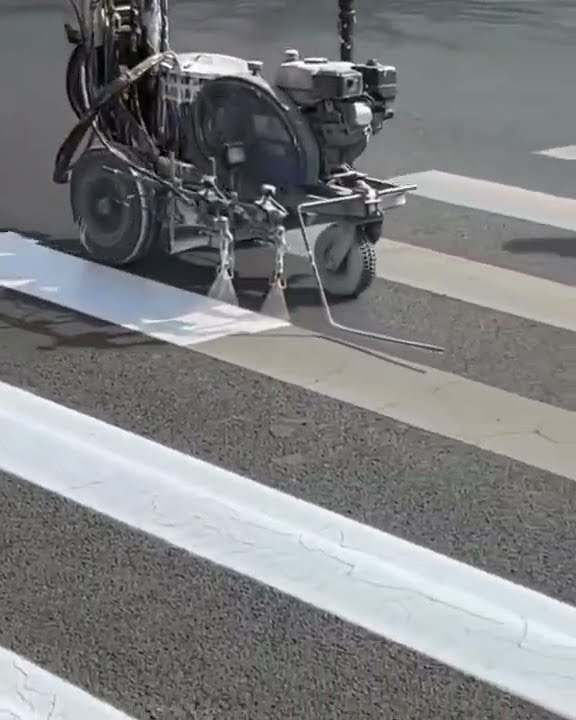

Smart Engineering - Zebra Crossing

Market Survey

Mobile Robot Navigation Project #1 using the 914 PC-BOT and Kinect | James Bruton

This is the first part/background to my new project series about mobile robot navigation. More at: http://xrobots.co.uk/pcbot/You can join my facebook page a…

Useful Resources

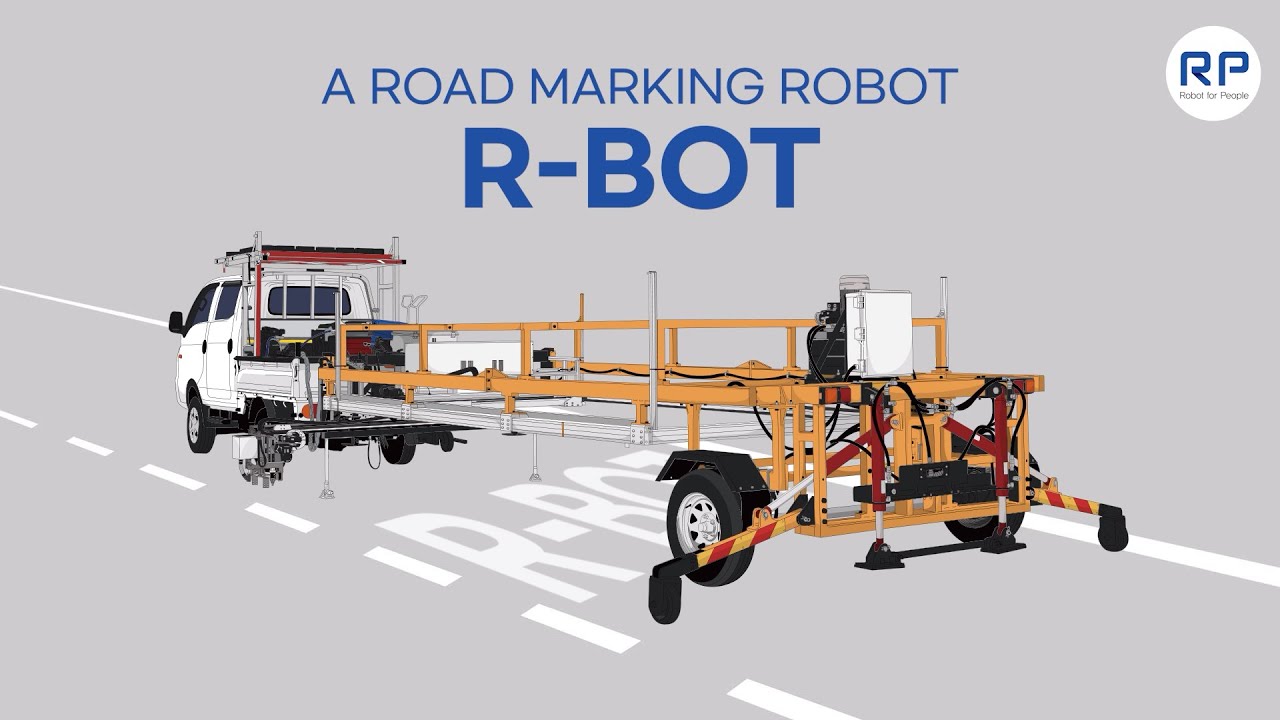

Introducing R-BOT, a road marking robot

“Introducing R-BOT, a road marking robot”Road marking construction with many fatal accidentsR-BOT was developed to create a construction site that saves peop…

Skills Required

- PCB Design

- Manual Soldering

- Electronic Testing

- ESP32 Programming

- Milling

- CAD design

- Sheet cutting

- CNC lathe turning