20251ROB2: Industrial Manipulator - Robotic Arm

Brief Introduction & Functionality

An industrial manipulator is a type of robotic arm designed to mimic the movement and functionality of a human arm, often used in manufacturing, assembly, and material handling applications. These robotic systems are composed of multiple joints and actuators, allowing for multi-degree-of-freedom (DOF) movement and precise control.

OpenManipulator, an open-source robotic arm by ROBOTIS, is a popular lightweight manipulator used in research and education. However, its payload capacity (~500g) limits its industrial applicability.

To address this, we propose the development of an updated manipulator, inspired by OpenManipulator’s modular design and ROS compatibility, but engineered to carry heavier payloads up to 4–5 kg, making it suitable for semi-industrial and small-scale automation tasks.

Skills Required

- CAD Design using Autodesk Fusion / CAD Design

- 3D Printing

- PCB Design using EasyEDA

- PCB Milling

- Electronics Testing

- CNC Machining

Useful Resources

- Robotic Arm - 3D printed parts for low payload. It also contains an Computer Interface to control the arm.(Open-sourced)

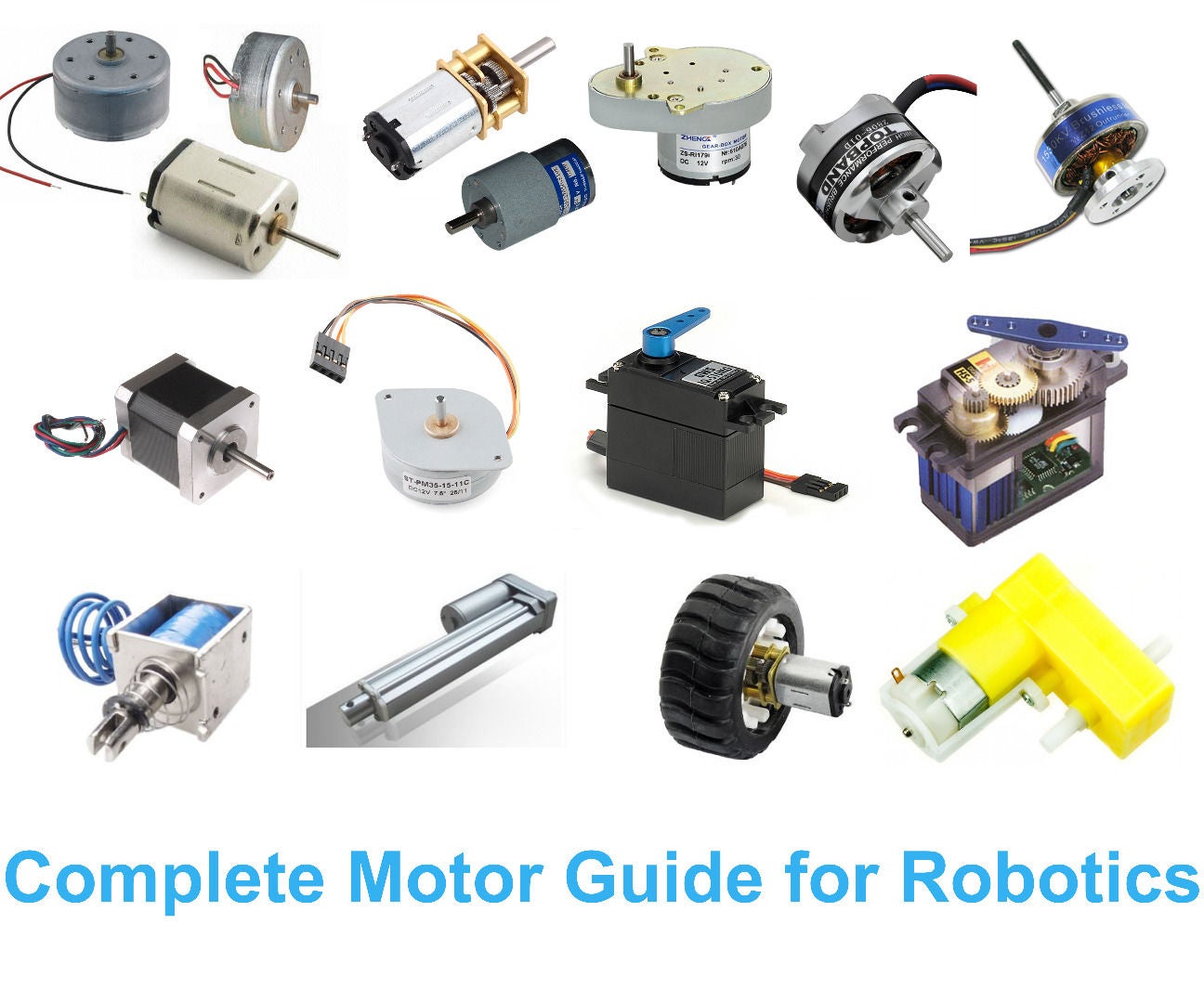

- Complete Motor Guide - Important source to understand which can help in taking decision regarding motor selection.

- Step 2 - Need of Motor controllers

- Step 3, 4, 5, 6 - Brushed DC motor, Working of H-Bridge, Controlling using single transistor, Controlling using H-bridge

- Step 7 - DC geared motor & working {Important relation between RPM and torque.}

- Step 11: How You Select Correct Motor for Your Robot?

- How does servos work ?