20251ROB1: Floor Cleaning Robot

Brief Introduction & Functionality

The proposed floor cleaning robot is a modified version of the Karcher S 4 Twin Push Sweeper, originally designed for manual collection of dust, leaves, and other dry debris. This project aims to transform the manually-operated sweeper into a semi-autonomous or fully autonomous robotic floor cleaner tailored for use in a woodworking shop environment. The robot will be enhanced with sensors, control systems, and drive mechanisms to navigate and operate autonomously within workshop conditions, efficiently collecting fine wood dust, chips, and small debris scattered across the floor.

Sweeping and Debris Collection (Already present):

- Retains the original dual side brushes and central roller of the Karcher S 4 Twin for effective mechanical sweeping.

- Designed to collect fine wood dust, small chips, and other workshop debris into the onboard collection container.

Drive System Integration:

- Motors will be retrofitted to the wheel assembly to provide powered mobility.

- Motor drivers and a control board (such as Arduino or Raspberry Pi) will manage motion and enable variable speed and direction control.

Power and Control:

- Operates on a rechargeable battery system for mobility without the need for tethered power.

- An onboard microcontroller or single-board computer will handle motion control, sensor input (if added), and execution of the cleaning routine.

Design Scope

- Modification of existing Karcher Push Sweeper (Source)

To be discussed and decided !

Tentative List of Components

Below list may vary according to the project's requirements and scope of work.

Fabrication

- Karcher Push Sweeper

- Acrylic Sheets

- 3D printed casings for Microcontroller

Electronic Components

- Geared DC Motors

- Motor Drivers

- Buck Converters

- Ultrasonic distance Sensors

- Microcontroller / Controller Board (Arduino / Raspberry PI / ESP32)

- Battery Pack

- Power Switch

- Wires, Connectors & PCB

- HC-SR04-Ultrasonic Range Finder

Mechanical Components

- Bearings

- Motor mounts

- Track Belt & Pulley System (if using tracked drive)

- Chassis(Main body of the robot) modification

- Dust/Debris Collection Tray Enhancements

Skills Required

Tentative Skills

- Arduino Programming

- PCB Design using EasyEDA

- PCB Milling

- Electronic Testing

- Circuit Simulation using TinkerCAD

- Laser Cutting - Acrylic

- CAD Design / CAD Design using Autodesk Fusion

- 3D Printing

- CNC Milling

Market Survey

- Karcher Push Sweeper

Kärcher Push sweeper S 4 Twin

Household Hand Sweeping Machine Without Electricity 360 Degree Rotating,Automatic Cleaning Push Sweeper Broom Dustpan Trash Bin Product Feature.

Useful Resources

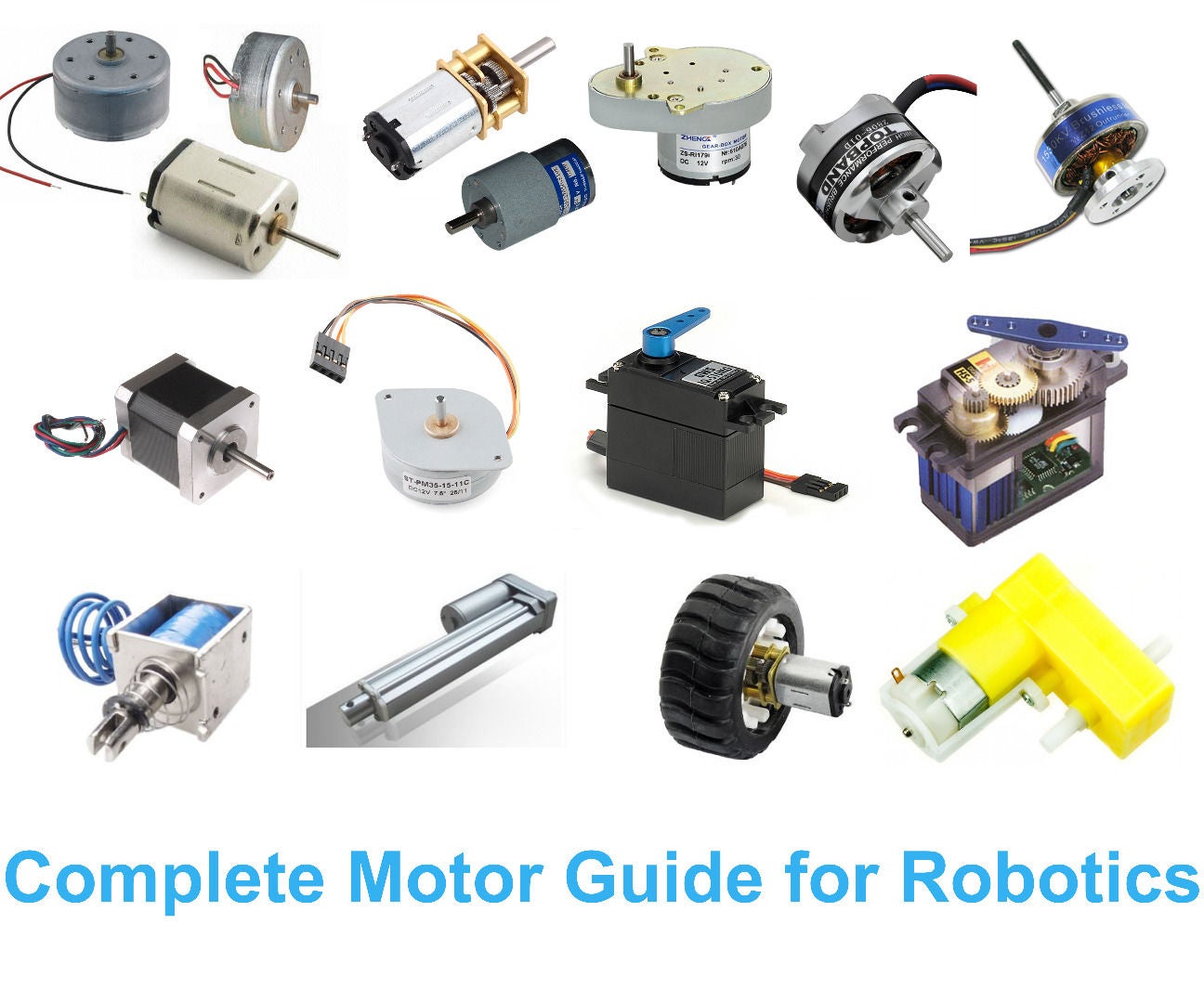

- Complete Motor Guide - Important source to understand which can help in taking decision regarding motor selection.

- Step 2 - Need of Motor controllers

- Step 3, 4, 5, 6 - Brushed DC motor, Working of H-Bridge, Controlling using single transistor, Controlling using H-bridge

- Step 7 - DC geared motor & working {Important relation between RPM and torque.}

- Step 11: How You Select Correct Motor for Your Robot?

Complete Motor Guide for Robotics

Complete Motor Guide for Robotics: Robot is an electromechanical device which is capable of reacting in some way to its environment, and take autonomous decisions or actions in order to achieve a specific task. Roboticists develop man-made mechanical devices that can move by themsel…

- HC-SR04 Ultrasonic Sensor - It works by sending sound waves from the transmitter, which then bounce off of an object and then return to the receiver.

Getting Started with the HC-SR04 Ultrasonic sensor

A basic introduction to the low cost and accurate HC-SR04!