20251MT1: Digital Tyre Pressure Inflator

A tyre inflator is a compact, portable air compressor used to inflate vehicle tyres. It works by drawing in ambient air, compressing it using a motor-driven piston, and delivering it through a hose into the tyre valve. It is a rechargeable, cordless inflator that features preset modes, a digital pressure gauge, and automatic shut-off.

This inflator is especially useful for:

- Emergency roadside tyre inflation

- Inflating sports equipment or bicycle tyres

- Avoiding petrol station queues for air

- Maintaining correct tyre pressure for safety and fuel efficiency

Market Survey

of Rs 1789 - bigbasket

Now available at Rs 1789

Portable Tire Inflator – 150 PSI Cordless Air Compressor w/ Power Bank & Flashlight

3-in-1 cordless inflator! 150 PSI, 17L/min, auto shut-off. Doubles as power bank & flashlight. Fits in your trunk—ideal for road trips. 25x20cm.

Buy Shakti Platinum Cordless Tyre Inflator 17 LPM Air Flow 150 PSI 2x2000 mAh Battery LED Flash Light with Accessories Online at Best Prices - Industrybuying.

Buy Shakti Platinum Cordless Tyre Inflator 17 LPM Air Flow 150 PSI 2x2000 mAh Battery LED Flash Light with Accessories Online in India on Industrybuying.com. All Genuine Products ✔ Lowest Prices ✔ Free Shipping ✔ EMI & COD

Useful resources

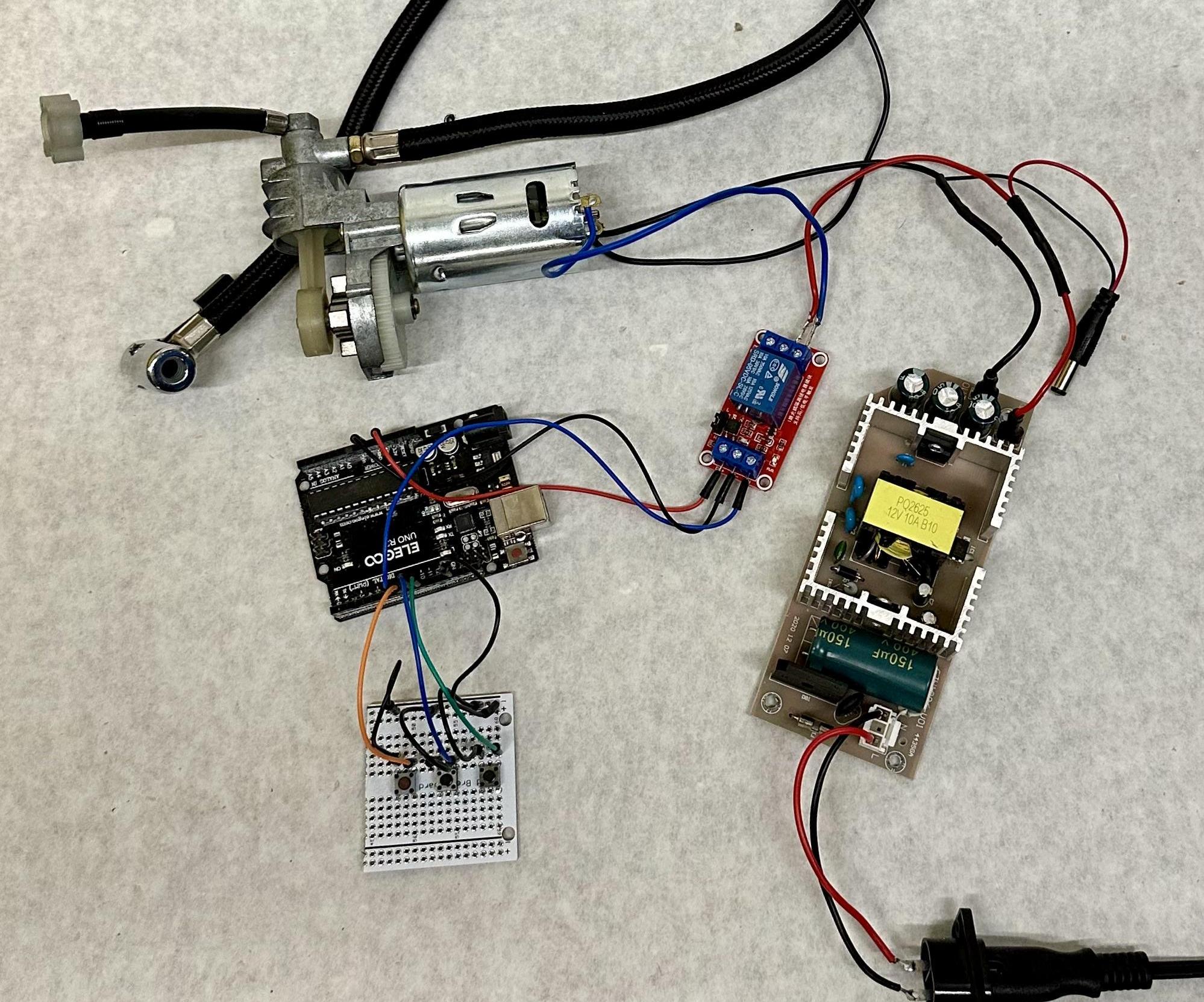

12 Volt Air Pump Controlled by Arduino Uno

12 Volt Air Pump Controlled by Arduino Uno: This is an instruction for how to use a relay and Arduino Uno to control an air pump. I worked on this for a class art project that required an open hardware aspect. The general system is simple: an Arduino controls a relay connected to the air pump…

Skills required

| Skill | Requirement in Project |

|---|---|

| Manual Soldering | Required to connect components like relay, pressure sensor, switches, display, battery module, and Arduino/ESP32. |

| Electronic Testing | Required to verify air pump control, pressure readings, auto shut-off, battery voltage levels, and safety operation. |

| Arduino Programming | Required if you use Arduino to control the air pump, read pressure sensor, and manage preset modes. |

| ESP32 Programming | Required if using ESP32 for advanced features (Bluetooth/Wi-Fi for app control or pressure logging). |

| CAD Design | Required to design the enclosure: fit for battery, air pump, buttons, display, and vents for airflow. |

| 3D Printing SLA | Required for fabricating precise or small parts of the enclosure (e.g., front panel). |

| PCB Design | Required to create a clean, compact board integrating the relay, sensor interface, and MCU (for durability & neatness). |

| PCB Milling | Required if you are fabricating the PCB in-house instead of sending it to a PCB manufacturer. |

| Wood Working | Required if you choose to build the outer casing from wood (unusual for a handheld device, but possible). |

| Sheet Metal Cutting | Required if casing is made from aluminum or steel for durability and heat dissipation. |

| Sheet Metal Bending | Required if using folded metal design for compact, rugged case (needs metal tools or workshop access). |

| Acrylic Sheet Cutting | Required to create a window for digital display or protective panel on control face. |