20251A9: Auto-Sensing Solder Fume Extractor

Brief Description & Functionality

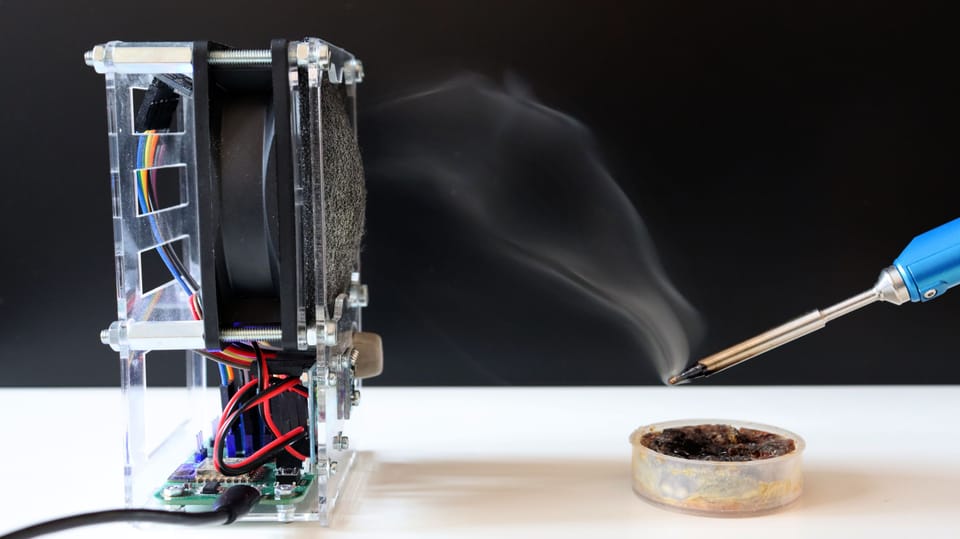

An auto-sensing solder fume extractor is a device designed to remove harmful fumes and particulates produced during soldering (especially when solder contains flux or lead). The equipment is capable of auto-sensing fumes, controlling fan speed, or turning its power on/off triggered by soldering activity. The advantages of this automatic device include

- It's not required to switch off the suction fan every time you take a break from soldering.

- The fan speed adjusts itself based on the fume being generated during soldering or desoldering. Less power is consumed.

- The noise of the fan can be irritating when soldering for long hours near a non-automated fume extractor equipped with a high-speed fan. The automated one speeds up only when required. They are suitable for lab or office settings.

- This is a cheap solution for room air purification that uses ductless or enclosed systems.

These are some of the features of the equipment and their respective functions

| Feature | Description |

|---|---|

| HEPA + Activated Carbon Filter | Captures microscopic particles and absorbs chemical fumes. |

| Auto Start/Stop | Detects soldering iron activity or temperature to start/stop the fan. |

| Variable Fan Speed | Lets you adjust airflow based on the intensity of work. |

| Flexible Duct or Arm | Allows precise positioning near the soldering point. |

| Filter Replacement Alert | Tells you when to change the filter. |

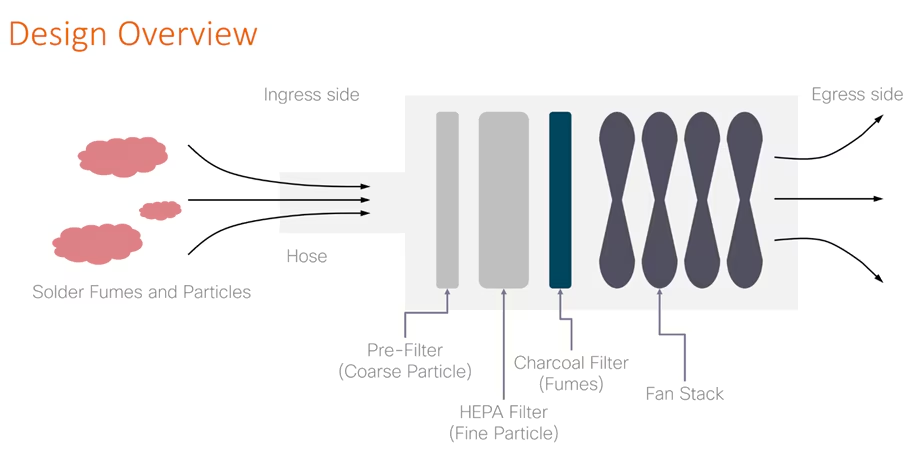

The physics behind fume extraction can be best described by the principles of fluid dynamics. A smoke sensor detects the fume and activates a mini exhaust fan. A pressure differential is created by the fan rotor. The spinning blades push air outward, lowering the pressure behind the fan. This phenomenon is supported by Bernoulli's principle. Due to the blade shape, it creates a high velocity of air at the fan inlet; hence, the pressure drops there. Polluted air from the higher-pressure side flows toward the low-pressure zone at the fan inlet. A series arrangement of a pre-filter, HEPA filter, and charcoal filter purifies the polluted air. The comparatively fresher air is recirculated into the room. A schematic drawing of the design of the fume extractor is shown below.

There can be variations in the way a fume extractor can be automated. Motion sensors can be utilized to detect whether a soldering iron is moved outside its holder. Also, a temperature sensor can detect the temperature of the soldering iron and determine whether soldering is occurring.

Market Survey

Bofa International's Electronic Fume Extractors

Useful Resources

Make your Own Auto-Sensing Solder Fume Extractor

Motion-Activated Solder Fume Extractor With Lamp

Solder Fumes Extractor Circuit

Automatic Solder Fume Extractor

Skills Required

- Arduino programming

- Circuit simulation

- PCB design

- PCB milling

- Manual soldering

- SMT soldering

- Electronic testing

- CAD modelling

- 3D printing (FDM)