20251A7: Automated Wire Cutter

Automated Wire cutters are used in industries to measure and cut the wires to exact specifications without manual intervention. With this type of automated wire cutter, one can increase the accuracy and repeatability of the wire cutting process maintaining high production rates.

Many industrial wire cutters has additional capability of stripping the wires of desired length at both the ends of wire being cut.

These wire cutters have applications in various industries like automotive, aerospace and electronics where large quantity of wiring need to be handled along with high precision.

How Does Automatic Wire Cutter Work

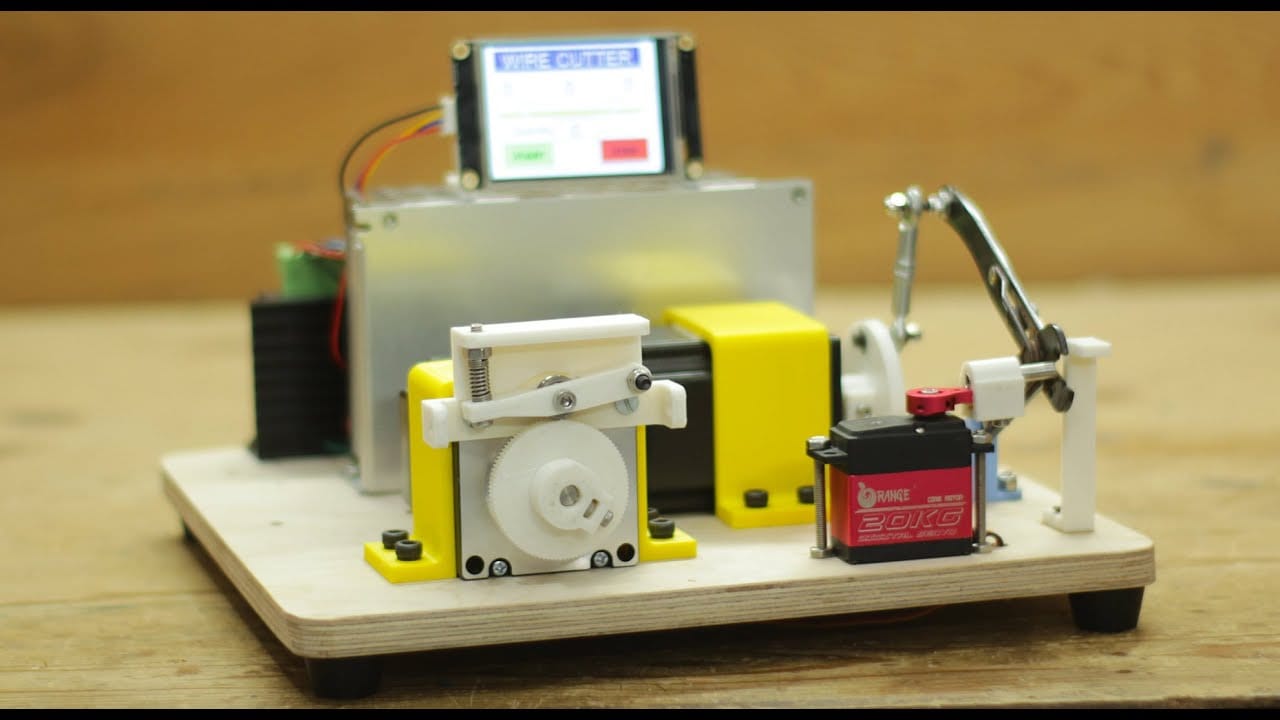

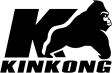

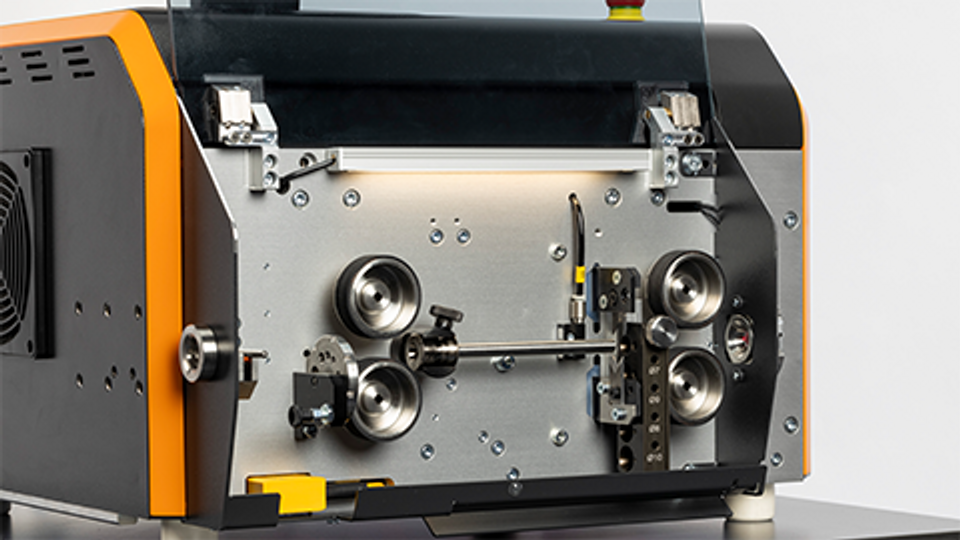

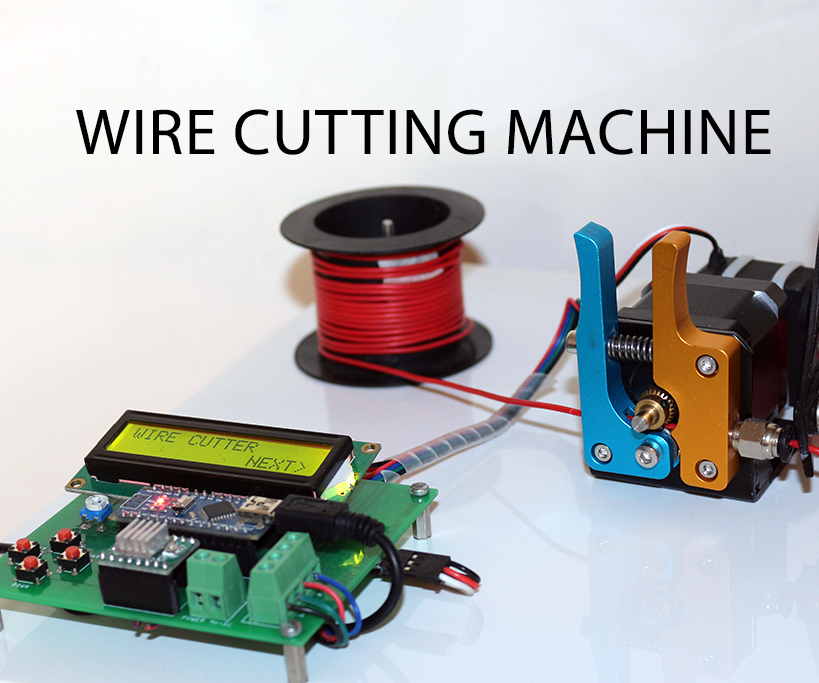

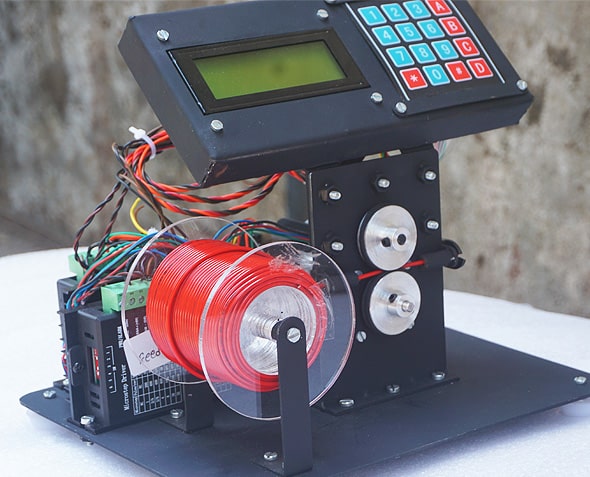

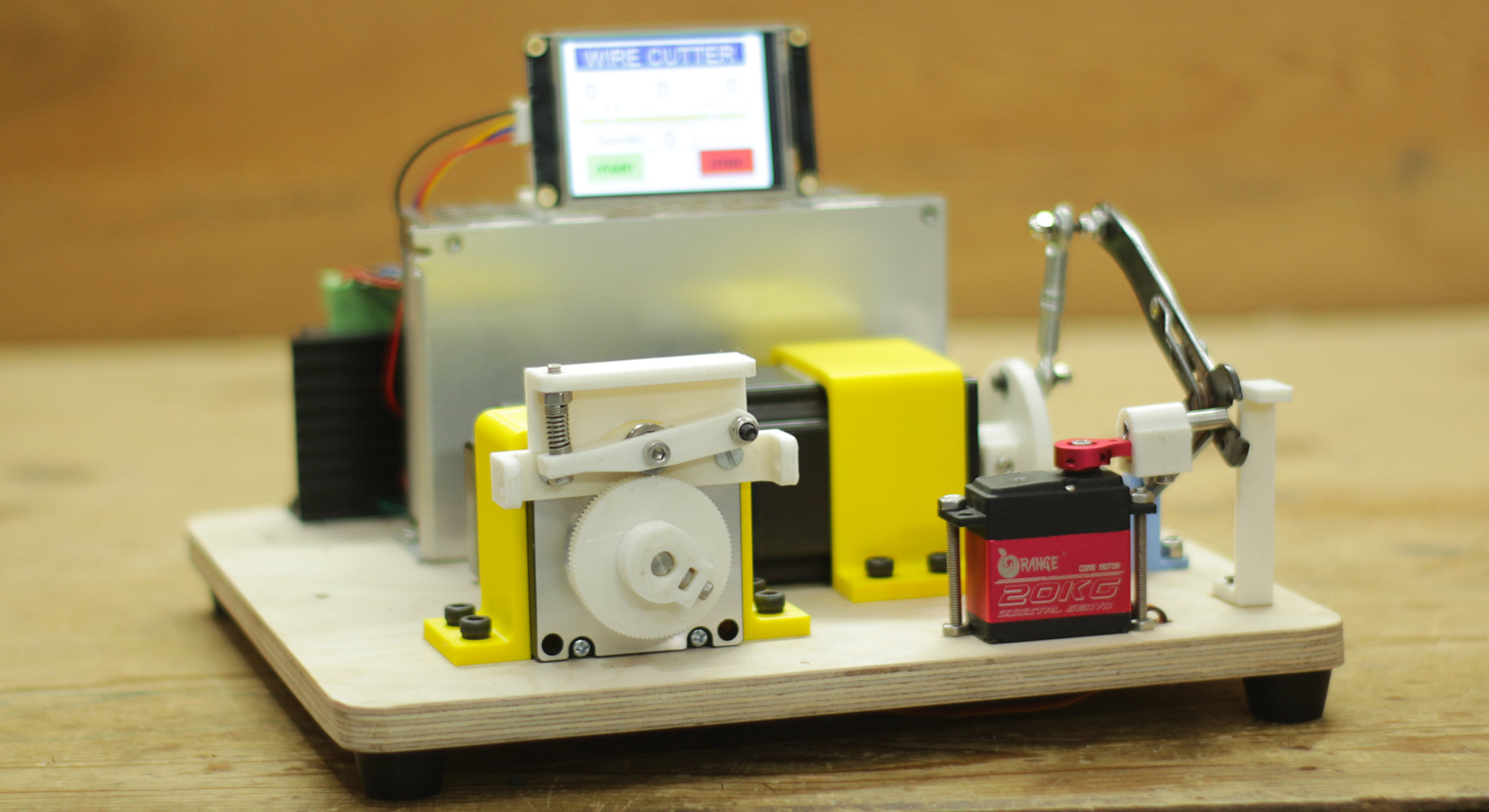

An automatic wire cutter works by integrating a feeding mechanism, a cutting unit, and a stripping system, all controlled by a microcontroller. First, the wire roll is mounted on the machine and guided between two the rollers. A stepper motor, driven by a motor driver, rotates these rollers to feed the wire forward.

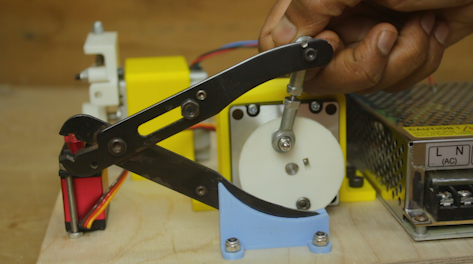

The length of the wire is continuously monitored using an encoder or limit switch feedback, ensuring precise measurement as per the length set by the user through a keypad or software interface. Once the required length is reached, the microcontroller sends a signal to a cutting mechanism—usually a pair of hardened steel blades actuated by a servo motor or a pneumatic cylinder—which quickly shears the wire.

Suggestive List of Materials

- Wooden Base

- Wire cutting blades

- Servo Motors

- Motor Drivers

- SMPS

- ESP32 Microcontroller/Arduino

- Rollers and other fitting fixtures

Market Survey

Useful Resources

Skills Required

- Wood Working

- 3D Printing

- PCB Design

- Arduino Programming

- Fabrication