20251A5: Roller Conveyor

Brief Description & Functionality

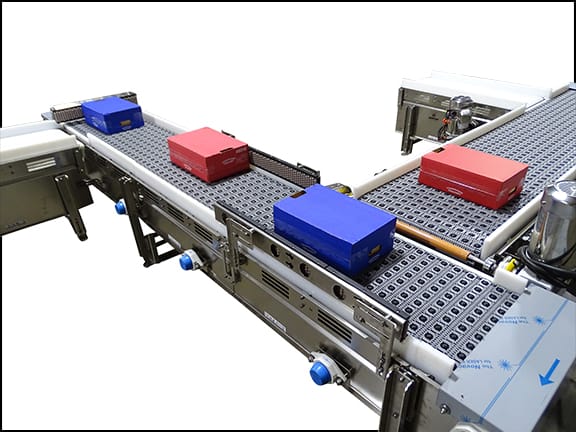

A Roller Belt Conveyor is a type of material handling system that combines rollers and a moving belt to transport goods over short to medium distances. Commonly found in factories, airports, logistics hubs, and automated assembly lines, these systems are known for their durability, versatility, and efficiency.

- Ideal for heavy or bulky items

- Reduces manual labour and improves productivity

- Supports automated material flow

- Scalable for both industrial and commercial operations

Working Principle:

Roller belt conveyors consist of a continuous belt supported by a series of rollers. The system operates as follows:

- Drive Pulley rotates, moving the belt

- Return Rollers support the underside of the belt

- Rollers reduce friction and support the load

- The belt carries items from infeed to outfeed end

- Power is provided via electric motors with gearboxes

Different configurations include flat belts, trough belts, inclined conveyors, and curved paths, depending on application needs.

3200 Series Conveyors with Intralox Activated Roller Belt Technology Carton Application

A customer recently needed a system to move various sized cartons through two inkjet printers. During this process, the carton needed to be justified and the…

Market Survey

Automatic Live Roller Conveyor

Saifi Con-Fab System Private Limited - Offering Automatic Live Roller Conveyor, Capacity: 1-50 kg per feet at ₹ 40000/unit in Faridabad, Haryana. Also find Roller Conveyor price list | ID: 11373811588

Useful Resources

Timing belt conveyors

Customised toothed belt conveyors with various drivetrains ✔ Minimal interfering contours ✔ easydrive®

Skills Required

- CAD design

- PCB Design

- Sheet cutting

- Sheet bending

- ESP32 Programming

- Milling

- Drilling

- Electronic testing

- Manual Soldering

- Circuit Simulation